How does automatic washing screen changer work

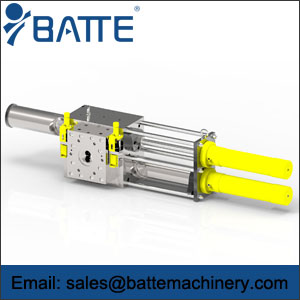

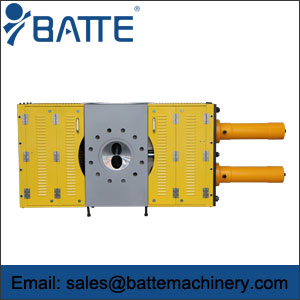

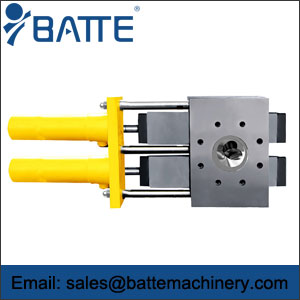

The screen changer is mainly used to filter out foreign particles and impurities when the plasticizing material flows through the filter screen. The purpose of using the screen changer is to ensure that one of the two sets of filtering devices is in the flow path of the melt extrusion material at any time during operation.

When the impurities on the filter screen gradually accumulate in the screen changer, the melt pressure increases accordingly; when the melt pressure before the filter screen reaches the set value, the backwash plunger of the screen changer will move downward under the push of the hydraulic cylinder, and a small part of the melt will flow backward, bringing out the impurities accumulated on the filter screen; When the melt backflow time reaches the preset time, the backwash plunger starts to move upward under the action of the hydraulic cylinder. A small part of the melt backflow will bring out the impurities accumulated in the filter screen. After the backflow reaches the preset time, the backwash plunger will return to its original position. In this way, the backwash screen changer realizes the process of automatic cleaning of the filter screen and the purpose of cleaning the filter screen.

More about screen changer products:

Batte is a professional screen changer manufacturer, supplying screen changer, especially screen changer for extrusion mould