Application and development trend of non-stop screen changer for extruder

In the process of plastic extrusion production, there may be various impurities and fine crystalline particles with incomplete plasticization in the raw materials. Even for brand new materials, there may be impurities present during transportation and production. If not filtered, it can cause a decrease in product quality, an increase in defective products, and even damage the extrusion equipment, leading to production interruption.

As an essential equipment in the production process of the extrusion industry, the non-stop screen changer of the extruder can not only effectively filter impurities in raw materials and improve product quality, but also reduce material loss, time cost, and labor cost caused by screen changing, resulting in improved production capacity efficiency and energy conservation and consumption reduction of the production line. At present, the performance of domestic screen changer equipment is uneven. Only by achieving smooth switching of filtering stations under high temperature and high pressure conditions without material leakage can it be called a qualified extruder screen changer without stopping the machine.

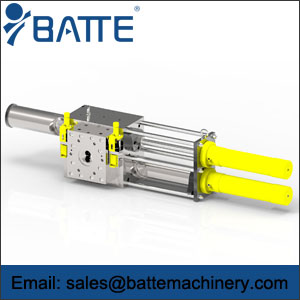

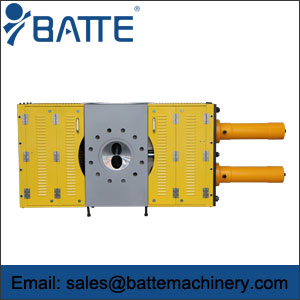

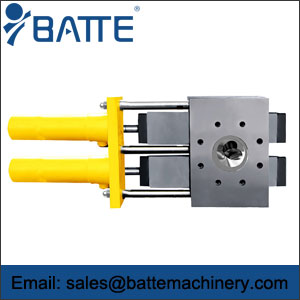

hydraulic extrusion screen changer for plastic extruder

In addition to basic quality assurance, the extruder non-stop screen changer product also optimizes the flow channel design, which can not only achieve non-stop and no material leakage during screen changing, but also completely avoid defective products caused by bubbles generated during the screen changing process. In order to meet the needs of users for higher efficiency, better quality, lower energy consumption, and minimum material loss, the new generation of large-area filter cartridge non-stop screen changer can provide an effective filtration area 6 times higher than ordinary screen changers, and can perfectly achieve backwashing function. It is particularly suitable for industry applications such as sheet materials, blowing film, drawing, modified granulation, and pipeline profiles.

BATTE Melt Pump is committed to providing better mesh changer and melt conveying solutions for manufacturers of chemical fiber, polymer, and rubber equipment products. With nearly 20 years of research and development and production experience, as well as thousands of installation and use cases of different types of equipment, we can provide optimized product solutions based on customer equipment, processing materials, and product technical requirements.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

More about screen changer products:

Batte is a professional screen changer manufacturer, supplying screen changer, especially screen changer for extrusion mould