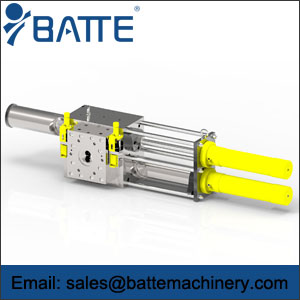

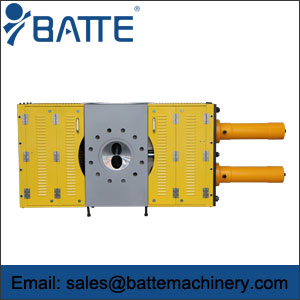

Application, working principle and parameters of single-column double-station quick screen changer

Used for granulation and drawing, plate and sheet, blown film, pipe, chemical fiber, adhesive, coating material, wire, cable, material co-mingled granulation, etc. Applicable to all thermoplastics.

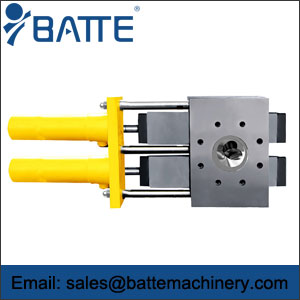

Single-column double-station screen changer, two detachable filtering stations are designed on the plunger, when working, one filtering station is inside the main body for melt filtration, and the other station is outside the main body for backup. When the impurities on the filter net accumulate to a certain degree during the work, it is necessary to change the net, you can press the operating handle button on the hydraulic station to start the accumulator hydraulic station for net changing action.

Single column screen changer features:

1, the use of pressure sealing (≤ 50Mpa) device, to meet any polymer high extrusion production, and more rapid screen change.

2、After rheological optimization of the honeycomb filter plate, effectively reduce the melt shear in the extrusion process.

3、High wear-resistant, high pressure-resistant, high-precision screen design improves the effective filtration area and filtration quality.

4、Rapid screen changing time is less than or equal to 2 seconds, internal heating device, energy saving and high efficiency.

5、No downtime to change the screen, no material leakage.

Single column screen changer technical parameters:

1、Maximum working temperature:350℃

2、Maximum working pressure: 50MPa

3、Differential pressure:≤25MPa

4、Applicable melt viscosity: 100~40000Pa.s

5、Heating method: electric heating/thermal media heating.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

More about screen changer products:

Batte is a professional screen changer manufacturer, supplying screen changer, especially screen changer for extrusion mould