What production fields are hydraulic backwash screen changers applied in?

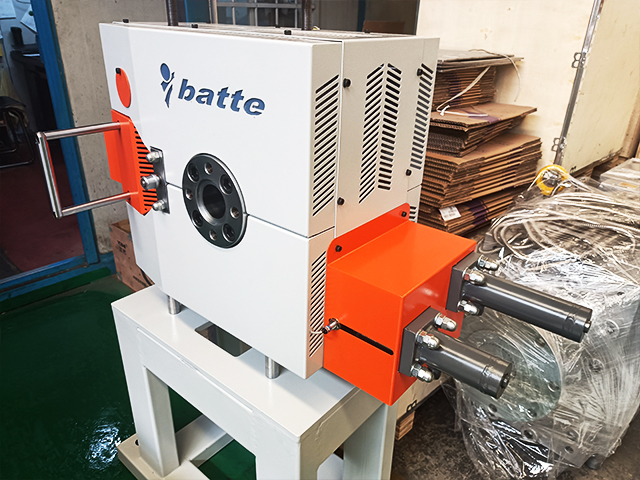

Hydraulic self cleaning screen changer, as an efficient and stable filtering equipment, has a wide range of applications in multiple fields. Its main function is to achieve rapid screen changing, cleaning, and filtering during continuous production, ensuring the smooth operation of the production line and stable improvement of product quality.

The hydraulic backflush screen changer plays an important role in the extrusion granulation production line from the plastic resin synthesis reaction device to bulk particles. Products in this field typically require high-precision filtration and quality control, and hydraulic backwash screen changers, with their efficient filtration and cleaning functions, can meet this requirement. In the synthesis process of plastic resin, it can effectively remove impurities and particles, ensuring the purity and quality of the resin. Meanwhile, in the extrusion granulation production line, the hydraulic backwash screen changer can quickly change the screen, ensuring the continuous and stable operation of the production line and improving production efficiency.

The ceramic extrusion production line is also an important application field of hydraulic backflush screen changer. The purity and particle size distribution of raw materials have a significant impact on the performance and quality of products in the ceramic production process. The hydraulic backwash screen changer can remove impurities and particles from raw materials through efficient filtration and cleaning, ensuring the quality and performance of ceramic products. In addition, the hydraulic backwash screen changer can also adapt to harsh environments such as high temperature and high pressure in the ceramic production process, ensuring the stable operation of the production line.

The polymer (plastic and rubber) molding production line is another important application field of hydraulic backwash screen changer. In this field, hydraulic backwash screen changers are widely used in multiple processes such as film blowing, casting, sheet materials, pipes, profiles, plastic recycling, granulation, drawing, underwater cutting, masterbatch granulation, and extrusion lamination production lines. It can quickly change screens, clean and filter, ensuring the purity and stability of polymer melts, thereby improving product quality and performance. At the same time, the hydraulic backwash screen changer can also adapt to the characteristics and process requirements of different polymer melts, achieving personalized customization and production.

In addition to the three main application areas mentioned above, hydraulic automatic self cleaning screen changers are also widely used in other fields. For example, in industries such as chemical fibers, rubber products, paint coatings, and food processing, hydraulic backwash screen changers can play their efficient filtering and cleaning functions, improving product quality and production efficiency.

In summary, hydraulic backwash screen changers have been widely used in multiple fields due to their efficient, stable, and reliable performance. With the continuous progress of technology and the continuous expansion of the market, the application scope of hydraulic backwash screen changer will continue to expand, providing strong support for the production of more industries.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071