What is the function of the PP PE sheet extrusion screen changer?

The PP PE sheet extrusion hydraulic screen changer, as a key equipment on the plastic extrusion production line, undertakes the important task of filtering molten impurities and ensuring product quality. In the field of plastic processing, the performance of hydraulic screen changers is directly related to production efficiency and product quality. Therefore, it is particularly important to have a deep understanding and reasonable application of hydraulic screen changers for PP PE sheet extrusion.

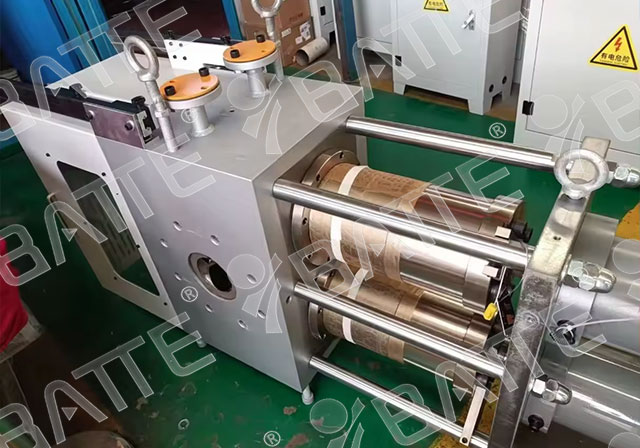

Firstly, let's explore the working principle of the hydraulic screen changer for PP PE sheet extrusion. Hydraulic screen changer usually consists of two filter screen bolts, each bolt containing a filter chamber. When the melt passes through the filter, impurities are effectively filtered, while the clean melt continues to flow to the next process. When it is necessary to replace the filter screen, the dirty filter screen bolt can be removed through the hydraulic device, while the other bolt remains in the operating position to ensure the continuity of the production process. This design eliminates the need for downtime during the network replacement process, greatly improving production efficiency.

The application of hydraulic screen changer is crucial in the extrusion process of PP PE sheets. Due to the high viscosity and fluidity of PP and PE materials in the molten state, the performance requirements for filtration equipment are also relatively high. The hydraulic screen changer, with its efficient and reliable filtration performance, can ensure the purity of the melt during the extrusion process, thereby improving the quality of the sheet. In addition, the hydraulic screen changer also has a good sealing structure design, which can maintain good sealing performance under high temperature and high pressure conditions, effectively preventing the occurrence of material leakage and seepage.

The advantages of hydraulic screen changers are not only reflected in their filtration performance, but also in their ease of operation and maintenance costs. The hydraulic screen changer adopts automatic control, which is simple and convenient to operate, and can greatly reduce the labor intensity of workers. Meanwhile, due to its convenient replacement of filter screens and relatively low maintenance costs. In addition, the hydraulic screen changer also has good durability and can operate stably in long-term, high load working environments, creating greater economic benefits for enterprises.

Of course, when using the PP PE sheet extrusion hydraulic screen changer, there are also some issues that need to be noted. Firstly, it is important to ensure that the installation position and connection method of the hydraulic screen changer are correct to avoid malfunctions or performance degradation caused by improper installation. Secondly, it is necessary to regularly check the use of the filter screen and replace severely worn filters in a timely manner to ensure the filtration effect. In addition, it is necessary to pay attention to the operating status of the hydraulic screen changer, and promptly handle any abnormal situations to ensure the smooth progress of the production process.

In short, The hydraulic screen changer for PP PE sheet extrusion has broad application prospects in the field of plastic processing. By understanding its working principle, performance characteristics, and usage precautions, we can better apply this equipment, improve production efficiency, reduce maintenance costs, and create greater value for enterprises. With the continuous development of technology, it is believed that in the future, more hydraulic screen changers with superior performance and convenient operation will be introduced, bringing more convenience and benefits to the plastic processing industry.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071