How to choose a PE pipe extrusion screen changer?

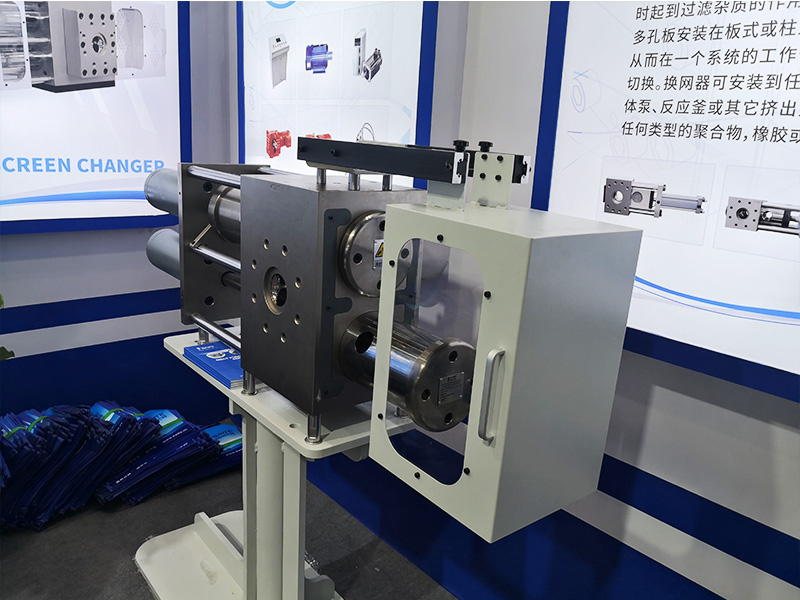

When choosing a PE pipe extrusion screen changer, the first thing we need to pay attention to is the type of screen changer. There are various types of screen changers in the market, such as manual screen changers, hydraulic screen changers, pneumatic screen changers, etc. The choice of type of screen changer mainly depends on factors such as production scale, production speed, and screen switching frequency. For example, for large-scale and high-speed production lines, hydraulic or pneumatic screen changers may be more suitable because they can achieve fast and automated screen changing processes, improving production efficiency.

Secondly, we need to consider the performance parameters of the screen changer. This includes screen changing speed, screen changing accuracy, filter screen size, etc. The speed of changing the mesh directly affects production efficiency, while the accuracy of changing the mesh is related to the quality of the product. The selection of filter size needs to be determined based on the extrusion amount of PE pipes and the service life of the filter.

In addition, the durability and maintenance convenience of the screen changer are also important factors that we need to consider. A high-quality screen changer should have good durability, be able to operate stably for a long time, and reduce the failure rate. Meanwhile, the maintenance of the screen changer should also be as convenient as possible to reduce maintenance costs and difficulties.

Finally, selecting reputable and experienced suppliers or brands is also an important aspect that cannot be ignored. These suppliers or brand lines usually have stable and well-established operations. After sales service system.

Overall, providing technical support for selecting timely PE pipes and extrusion maintenance for network replacement servers is a decision-making process that requires comprehensive consideration of multiple factors in production. We need to choose the most suitable screen changer based on our production needs, equipment conditions, and budget. Only in this way can we ensure the stable operation of the production line, improve production efficiency, and reduce production costs.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071