How to choose a screen changer for polystyrene applications and extrusion production lines?

Polystyrene, as an important synthetic resin, has characteristics such as colorless transparency, lightweight and durable, thermal insulation, etc. It is widely used in various fields such as packaging, construction, home furnishings, cosmetics, medical devices, and electronic products. Meanwhile, with the continuous development and improvement of extrusion technology, the extruder screen changer plays a crucial role in the production process of plastic materials such as polystyrene. This article will provide a detailed discussion on the application fields of polystyrene and the selection of extruder screen exchangers.

Firstly, the application of polystyrene in the packaging field is particularly prominent. Due to its lightweight, durable, and thermal insulation properties, polystyrene is often used to make various types of packaging materials, such as cling films, food containers, tableware, etc. These packaging materials not only effectively protect the product, extend its shelf life, but also improve its aesthetics and market competitiveness.

In the fields of architecture and building materials, polystyrene also plays an important role. Polystyrene foam is widely used in building insulation materials, wall insulation materials and floor insulation pads. Its lightweight, insulation performance, and thermal insulation performance are of great significance for energy conservation and insulation, helping to improve the energy efficiency and comfort of buildings.

In addition, polystyrene has a wide range of applications in household products, cosmetics and medical devices, electronic products, and other fields. For example, polystyrene can often be seen in household items such as furniture, electrical casings, hangers, toys, etc; Medical devices such as cosmetic bottles, drug containers, and test tubes are often made of polystyrene; In the field of electronic products, polystyrene is used to make TV cases, computer cases, mobile phone and tablet cases, etc. Its insulation and high temperature resistance are crucial for the protection and stable operation of electronic products.

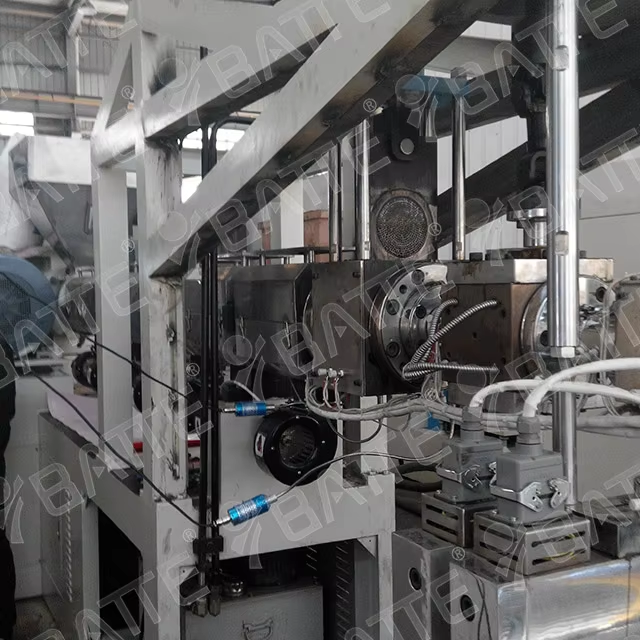

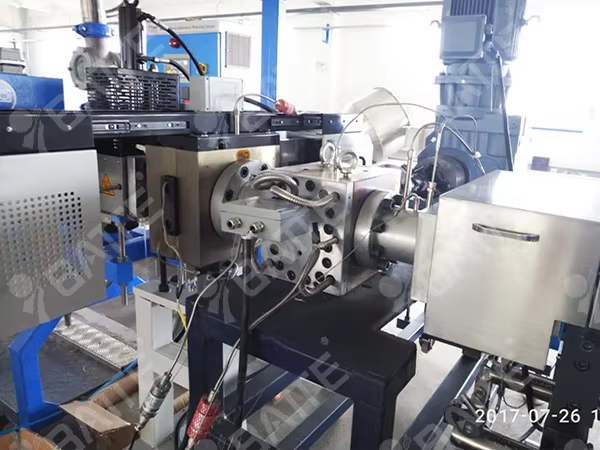

However, with the continuous expansion of the application of polystyrene, its production process also faces many challenges. Among them, the selection of the extruder screen changer is a key consideration. The extrusion screen changer is a manual or automatic switching device that includes one or more filters, used to filter out foreign particles and impurities during the plastic material flow filter screen. Its performance directly affects the quality and production efficiency of plastic materials such as polystyrene.

When choosing an extruder screen changer, the first thing to consider is the characteristics of the raw materials and production needs. Different raw materials have different melting points, melting points, corrosiveness, and flowability, so the requirements for the mesh changer are naturally different. At the same time, the type of product produced and the requirements for production continuity will also affect the selection of the screen changer. For example, for production lines that require continuous production and have high requirements for product quality, a screen changer with a large filtration area and good filtration effect should be selected to ensure the stability of the production process and product quality.

Secondly, the type and output of the extruder should be considered. The model and output of the extruder determine the size and filtration capacity of the screen changer. Usually, the diameter of the filter should not be lower than the diameter of the screw to ensure the filtration effect. At the same time, the processing capacity of the screen changer should also be matched with the output of the extruder to avoid wasting funds or affecting production efficiency.

Finally, it is also necessary to consider the service life and maintenance cost of the screen changer. High quality screen changers not only have a long service life, but also can reduce maintenance costs and improve production efficiency. Therefore, when choosing a screen changer, factors such as performance, price, and service life should be comprehensively considered, and a product with high cost-effectiveness should be selected.

In summary, polystyrene, as an important synthetic resin, has a wide range of applications in various fields. When selecting an extruder screen changer, comprehensive consideration should be given to factors such as raw material characteristics, production requirements, extruder type and output, as well as the service life and maintenance cost of the screen changer, to ensure the stability of the production process and product quality. With the continuous progress of technology and the continuous improvement of processes, it is believed that there will be more high-performance and high-efficiency extruder mesh changer products available in the future, providing more possibilities for the production of plastic materials such as polystyrene.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071