Precautions during transportation of screen changer

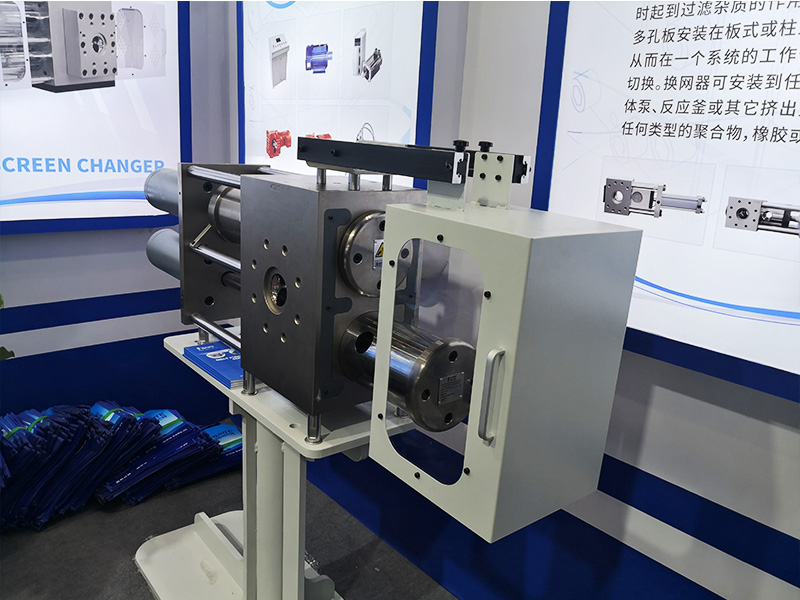

The screen changer, an indispensable and important equipment in the extrusion industry, is becoming increasingly prominent in its function and role. Many enterprises tend to choose this equipment when dealing with the filtration of molten materials to improve production efficiency and product quality. However, the purchase of equipment is only the first step, and the subsequent transportation process is equally crucial. After all, only a intact and undamaged device can ensure that it can be smoothly put into use upon arrival at the site.

During the transportation of the screen changer, we need to be extra careful to ensure its safe arrival at the destination. Firstly, before long-distance transportation, it is necessary to carefully inspect the equipment, remove the accessories and ship them separately to prevent collision or damage during transportation. At the same time, the moving parts on the equipment must be fixed and locked to prevent damage due to shaking, impact, or vibration during high-speed driving.

When the size of the screen changer is large and exceeds the transportation regulations of the transportation department, we need to carefully plan the shipping plan and closely communicate with the transportation department to jointly develop a suitable transportation route. In addition, before formal shipment, a comprehensive inspection of the walking device of the equipment, especially the towing and braking systems, is carried out to ensure their safety and reliability, and to avoid safety accidents during transportation.

After completing the above preparation work, fold up the supporting legs of the equipment to start shipping. During the transportation process, we should maintain an appropriate speed to avoid sudden braking or high-speed driving. For large equipment, clear signs should also be placed on the vehicle body to remind other vehicles to pay attention to safety. At the same time, assign a dedicated person to be responsible for the safety supervision of the equipment, ensuring that the transportation process is foolproof.

When the screen changer needs to be transferred over a small distance within the construction site, the preparation work is relatively simple. Just check the walking device to ensure everything is normal, then retract the support legs and use machinery with high traction such as bulldozers for transportation. During this process, it is also necessary to pay attention to the road conditions, especially the lateral slope, to avoid equipment damage due to instability.

In short, the transportation of the screen changer requires us to attach great importance, from equipment inspection, formulation of shipping plans to safety supervision during transportation, every step needs to be carefully planned and strictly executed. Only in this way can we ensure the safe and complete arrival of the screen changer at the destination, providing strong support for the production of the enterprise.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071