What are the application scenarios of start-up valves?

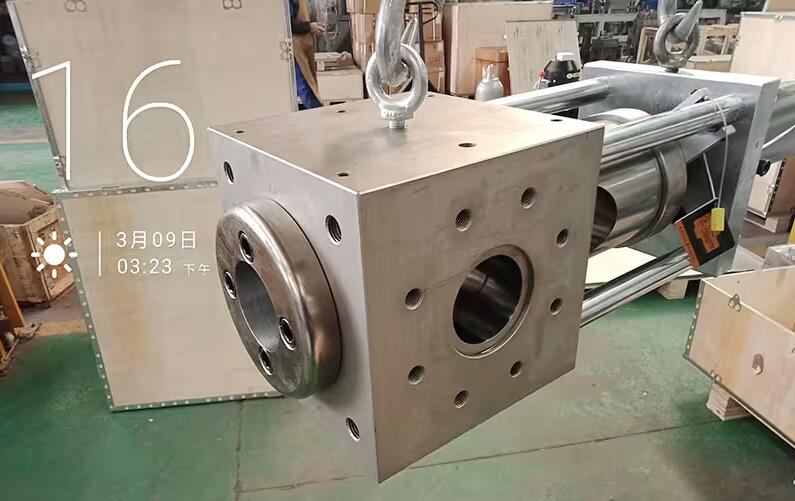

The start-up valve, also known as the discharge valve, finds diverse applications across various industrial sectors. Below is a detailed summary of its primary application scenarios:

I. Extrusion Production Line

Installation Position: The start-up valve is typically installed at the outlet end of the extruder barrel.

Functionality:

• Prior to startup, it is switched to the discharge position to expel residual material within the barrel. Once the material is normal, it is shifted to the working position to commence production.

• When used in conjunction with equipment such as screen changers or melt pumps, under exceptional circumstances (e.g., sudden pressure surge or overpressure in front of the screen changer or melt pump), the discharge valve can be set to open, safeguarding upstream equipment.

II. Polymerization Production Line

• Installation Position: Similarly, it can be installed at critical points within the polymerization line.

• Functionality: Akin to its role in extrusion lines, the start-up valve in polymerization lines also performs material discharging and equipment protection functions.

III. Underwater Cutting Production Line

Essential Application: In underwater cutting production lines, the start-up valve is virtually an indispensable component.

Functionality:

• Not only is it used for discharging material, but it also interlocks with underwater cutting controls. In the event of emergencies such as die orifice blockage, particle agglomeration, material entanglement, water pressure failures, or abnormal water temperatures, the start-up valve triggers an alarm and activates the discharge position for brief troubleshooting, ensuring uninterrupted operation of upstream equipment.

IV. Other Application Scenarios

• Corrosion Resistance: For corrosive materials, the start-up valve can undergo corrosion-resistant treatment or be crafted from corrosion-resistant materials to meet the demands of special production environments.

• Customizable Configurations: Clients can select various configurations for the start-up valve based on their specific requirements, including heating methods (electric or thermal medium) and customization of core components like accumulator hydraulic power stations and electric control cabinets.

In conclusion, the start-up valve plays a pivotal role across multiple industrial sectors, including extrusion, polymerization, and underwater cutting production lines. Its extensive application scenarios and flexible configuration options make it an indispensable and crucial device in industrial production.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071