What are the common application scenarios of screen changers?

The screen changer, as a widely used equipment in industrial production, has a variety of common application scenarios spanning multiple industries. Below are some of the main application areas:

1.Plastic Industry

Production of Plastic Pipes, Profiles, and Sheets: In plastic extrusion lines, the screen changer is used to automatically replace filters, removing impurities and moisture from molten plastic, thereby ensuring product quality and performance. Fully automatic screen changers enable continuous production without interruption, maintaining production continuity and stability.

2.Rubber Industry

Production of Rubber Products: For products such as tires, conveyor belts, and seals, fully automatic screen changers play a pivotal role in the production process. They enhance the surface smoothness and dimensional accuracy of products, filtering out impurities in rubber to ensure product quality.

3.Chemical Fiber Industry

Production of Chemical Fiber Products: For fibers like polyester, nylon, and polypropylene, fully automatic screen changers are used on production lines to ensure fiber quality and uniformity. By automatically replacing filters, they remove impurities from raw materials, improving fiber quality.

4.Petrochemical Industry

Liquid Material Filtration: Rapid, non-stop screen changers are utilized in the petrochemical industry to filter impurities from liquid materials such as lubricants and fuels, ensuring product purity and stability. This is crucial for enhancing overall product performance and extending product lifespan.

5.Paint and Coatings Industry

Production of Coatings: During the production of paint and coatings, screen changers rapidly and accurately filter out impurities, enhancing coating purity and stability. This is vital for ensuring coating performance and durability.

6.Food and Pharmaceutical Industry

Filtration of Liquid Foods and Pharmaceuticals: In the food and pharmaceutical industries, screen changers carry a higher mission. They rigorously filter liquid foods, pharmaceuticals, and other products, ensuring their hygienic safety. At the same time, their high efficiency significantly boosts production rates, providing valuable time and market opportunities for enterprises.

7.Other Industries

Other Areas Requiring Continuous Production: Industries such as textiles and papermaking also rely heavily on screen changers. In these sectors, screen changers ensure continuous production line operation, reducing downtime and enhancing both production efficiency and product quality.

In summary, screen changers have extensive applications across industries such as plastics, rubber, chemical fibers, petrochemicals, paint and coatings, food and pharmaceuticals. As industrial production continues to evolve, screen changer technology is also advancing and improving to meet the diverse demands of various industries for product quality and production efficiency.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

More about screen changer products:

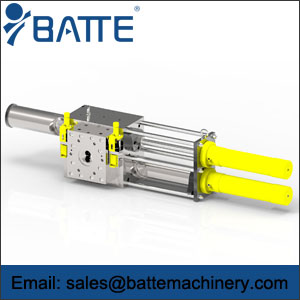

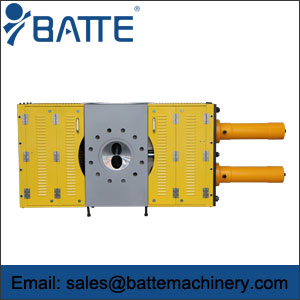

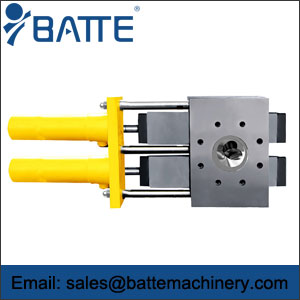

Batte is a professional screen changer manufacturer, supplying screen changer, especially screen changer for extrusion mould