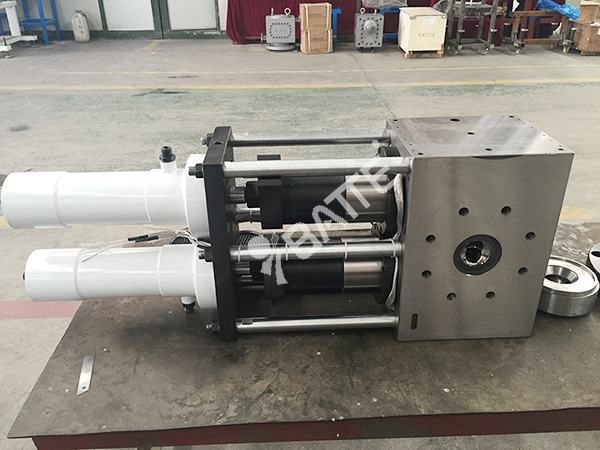

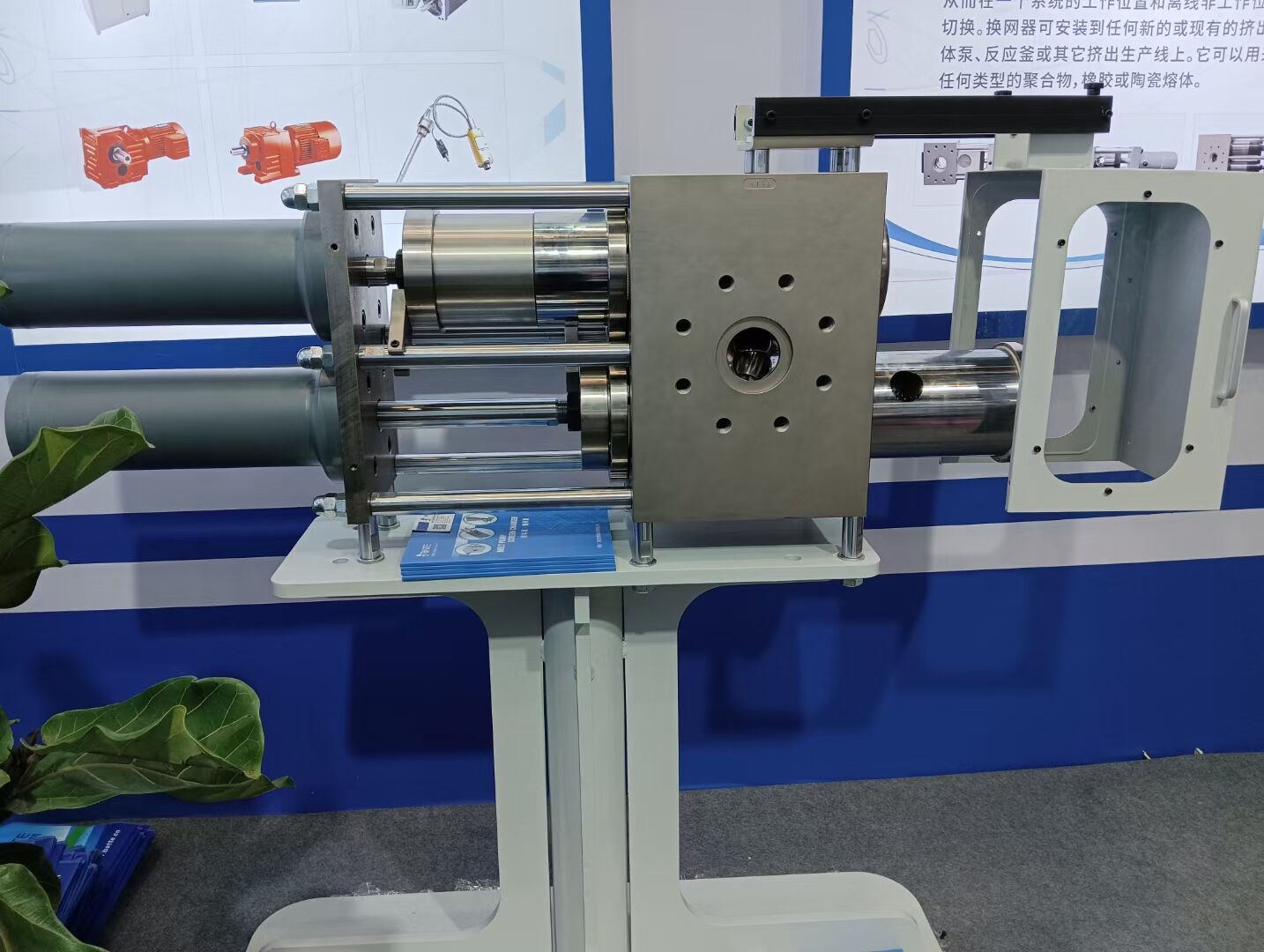

What are the advantages of the dual column hydraulic screen changer for cast film?

The double-column hydraulic screen changer for cast film production exhibits notable advantages in the film manufacturing process, primarily manifested in the following aspects:

I. Exceptional Filtration Efficacy

Fine Filtration: Equipped with a sophisticated filtration design, the double-column hydraulic screen changer for cast film effectively removes impurities from plastic melts, ensuring the quality of the final product. Its characteristic of zero impurity escape results in films with higher purity and consistency.

II. High Production Efficiency

Continuous Production: The dual-column design enables alternating filter replacement, ensuring uninterrupted production and eliminating downtime caused by screen changes. This design facilitates extended continuous production of products, reducing waste and enhancing overall production efficiency.

Stable Material Flow: During screen changes, the backup filter maintains continuous operation, ensuring stable material flow with minimal temperature fluctuations, minimizing the impact on production.

III. Ease of Operation

High Automation: Configurable with a PLC control system, the double-column hydraulic screen changer for cast film offers automatic alarm and control functions, simplifying operations and reducing labor costs. Screen changes are straightforward and labor-saving.

IV. Enhanced Durability

Resistance to High Temperature and Pressure: Manufactured with materials that withstand high temperatures and pressures, the screen changer operates stably in such environments without leakage. Its rigid sealing structure prevents material leakage, extending its service life.

V. Strong Adaptability

Versatility in Materials and Products: Suitable for the production of various raw materials and products, including PP, PE, ABS, and products such as cast films, blown films, and sheets, the screen changer performs exceptionally well across multiple application scenarios.

VI. Other Advantages

Minimal Pressure Fluctuations: As only one filter screen operates during screen changes, material flow pressure fluctuations are minimal, ensuring the stability of the extrusion process.

Sturdy Structure: The main body of the double-column screen changer is typically made of high-quality alloy steel subjected to nitriding treatment, resulting in a sturdy structure with strong load-bearing capacity.

Safety Design: Equipped with a safety shield, it effectively safeguards the operator's personal safety.

In conclusion, the double-column hydraulic screen changer for cast film boasts significant advantages in filtration efficacy, production efficiency, ease of operation, durability, and adaptability, making it an indispensable auxiliary equipment in the film production process.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071