The relationship between the extruder and the screen changer

The extruder and the screen changer have a close relationship in the field of plastic processing, which is mainly reflected in the following aspects:

I. Functional Collaboration

Extruder: An extruder is a mechanical device that relies on pressure and shear force to mold fully plasticized and uniformly mixed materials through a die head. It is widely used in industries such as plastics, rubber, synthetic fibers, etc., for producing products of various shapes and specifications.

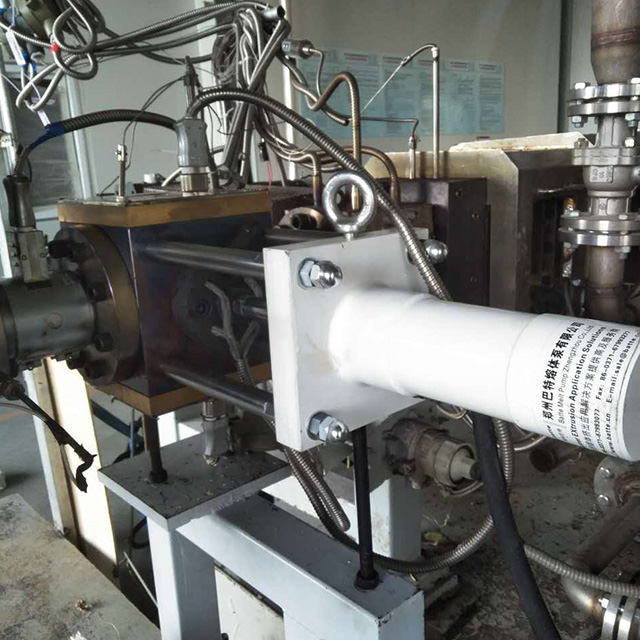

Screen Changer: A hydraulic extrusion screen changer is a manual or automatic switching device that incorporates one or more filter screens. It serves to filter out foreign particles and impurities from the plasticized material as it flows through the screens. Installed between the screw head of the extruder and the extrusion die head, the screen changer acts as a robust barrier, preventing impurities and foreign objects from entering the die head.

II. Complementary Roles

Role of the Extruder: Primarily, the extruder is responsible for plasticizing, mixing, and extruding materials such as plastics into desired shapes. However, during the extrusion process, the melt may decompose into some residues, and the raw materials may also contain impurities.

Role of the Screen Changer: Precisely to filter out these impurities and residues, ensuring that a pure melt can smoothly enter the extrusion die head, thereby producing high-quality plastic products. The screen changer, through its internal filter screens, intercepts impurities and particles from the melt, maintaining a smooth and unimpeded production process.

III. Structural Interconnection

The extruder typically consists of components such as the screw, barrel, die head, drive system, and control system, with the die head being the crucial part for extrusion molding.

The screen changer, on the other hand, comprises multiple parts including the body, sealing components, perforated plates, filter screens, and switching mechanisms. The materials and structural design of these components must meet the operational requirements under high-temperature and high-pressure environments to ensure the stability and durability of the screen changer.

IV. Application Examples

In the plastic processing industry, the combined use of an extruder and a screen changer has become standard practice. Whether producing pipes, sheets, films, or other plastic products of various shapes, the extruder is essential for plasticizing and extruding the material, while the screen changer filters out impurities and particles from the melt. This not only enhances the quality and purity of the products but also extends the service life of the extruder and reduces the failure rate.

In summary, the extruder and screen changer have an inseparable relationship in the field of plastic processing. Through functional synergy, complementary roles, and structural interconnection, they work together in the production process, providing a robust guarantee for the manufacture of high-quality plastic products.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071