Does the 25mm plastic HDPE PP rod extrusion production line need to be equipped with a screen changer?

Regarding the question of whether a screen changer is necessary for a 25mm plastic HDPE PP rod extrusion line, the decision primarily hinges on specific production requirements and material characteristics. Below are some considerations:

I. Function of the Screen Changer

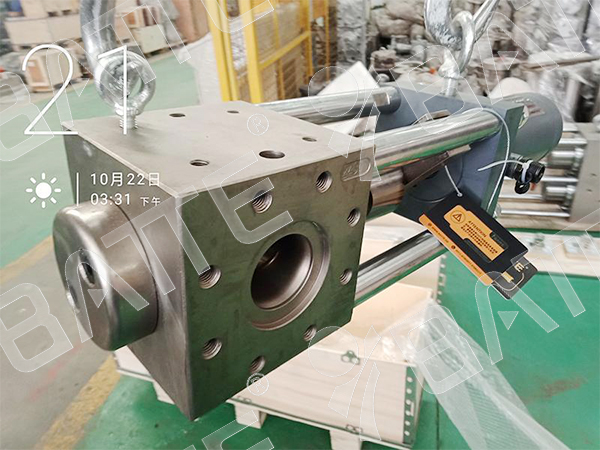

In plastic extrusion processes, the screen changer serves a crucial role in filtering out impurities and residues from the melt, preventing these contaminants from entering the extrusion die head. This safeguards against clogging of flow channels, product defects, or disruptions in production. During the prolonged plasticization and heating of the plastic melt, residues can decompose and impurities from raw materials may mix in, both of which can adversely affect the final product quality.

II. Factors to Consider

Material Characteristics: As common plastic materials, HDPE (High-Density Polyethylene) and PP (Polypropylene) may generate certain impurities or residues during the extrusion process. If there are high quality standards for the final product or if the raw materials contain significant impurities, installing a screen changer becomes necessary.

Production Needs: If the production line necessitates continuous and stable production of high-quality products, or if there are stringent requirements for the purity of the melt during the production process, a screen changer can enhance both production efficiency and product quality.

Cost-Benefit Analysis: Incorporating a screen changer adds complexity and cost to the equipment. However, in the long run, if it effectively enhances product quality and production efficiency, the investment may prove worthwhile. Thus, when considering the installation of a screen changer, a comprehensive cost-benefit analysis is imperative.

In conclusion, there is no definitive answer to whether a screen changer is necessary for a 25mm plastic HDPE PP rod extrusion line. The decision should be based on specific production requirements and material characteristics. If high product quality standards are in place, the raw materials contain substantial impurities, and the installation of a screen changer can achieve a favorable cost-benefit balance, it is advisable to install one to improve production efficiency and product quality.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071