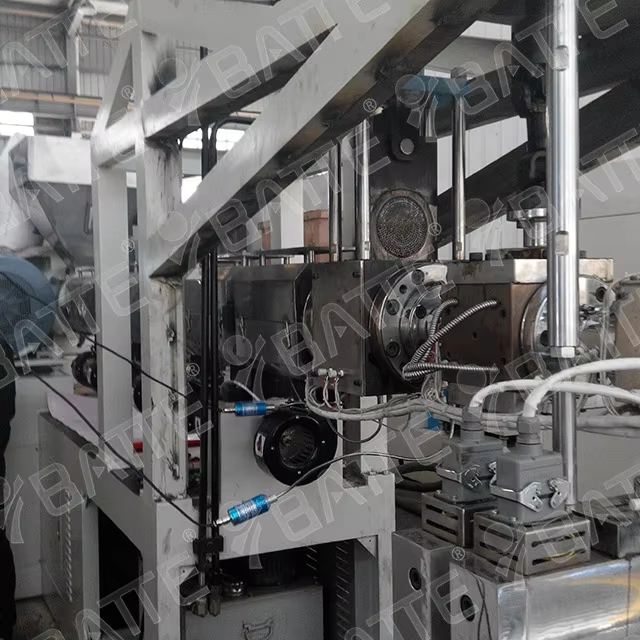

0.2-2.0mm polypropylene sheet extrusion screen changer

Regarding the Screen Changer used in the extrusion process of 0.2-2.0mm polypropylene (Polypropylene, PP) sheets, the following are some key information and explanations:

I. Role of the Screen Changer in Polypropylene Sheet Extrusion

During the extrusion of polypropylene sheets, the screen changer serves as a vital component. Its primary function is to filter impurities from the molten material, preventing them from entering the extrusion die and thereby impacting the quality and appearance of the sheets. By regularly replacing the filter screens, continuity in the extrusion process and consistent quality of the sheets are ensured.

II. Types of Screen Changers Suitable for 0.2-2.0mm Polypropylene Sheets

For polypropylene sheets with an extrusion thickness ranging from 0.2-2.0mm, screen changer types suitable for high precision and high output requirements are typically selected. Common types of screen changers include:

Sliding Screen Changer: This type of screen changer boasts a simple structure and ease of operation, making it suitable for scenarios where the speed of screen replacement is not particularly critical. It achieves quick screen changes by sliding the old screen out and pushing the new one in.

Rotary Screen Changer: The rotary screen changer offers higher screen change efficiency and a longer service life, making it suitable for situations requiring high production efficiency and strict quality standards for the sheets. It accomplishes continuous screen changes by rotating the filter screen from one side to the other.

Hydraulic Screen Changer: Driven by hydraulic cylinders, the hydraulic screen changer facilitates rapid filter screen replacement. This type of screen changer operates stably, boasts fast screen change speeds, and has minimal impact on the extrusion process of the sheets.

III. Factors to Consider When Choosing a Screen Changer

When selecting a screen changer for the extrusion of 0.2-2.0mm polypropylene sheets, the following factors should be taken into account:

Production Efficiency and Output: Based on the actual demands and output requirements of the production line, choose the appropriate type and specification of screen changer.

Sheet Quality Requirements: For scenarios where higher standards are set for sheet transparency, surface smoothness, and other quality aspects, a screen changer with higher filtration accuracy should be selected.

Operational Convenience: The screen changer should be easy and quick to operate, minimizing the impact of screen change time on the production line.

Maintenance Costs: Consider the maintenance costs and service life of the screen changer to select a cost-effective product.

In summary, for the extrusion of polypropylene sheets with a thickness ranging from 0.2-2.0mm, it is recommended to select the appropriate type and specification of screen changer based on the actual demands of the production line and sheet quality requirements. Additionally, prioritize products that offer operational convenience, low maintenance costs, and high cost-effectiveness to ensure continuous and stable operation of the production line and high-quality output of the sheets.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071