Screen changer used in BOPP film extrusion production line

The screen changer plays a vital role in the BOPP film extrusion production line, primarily tasked with filtering out foreign particles and impurities from the plasticized material as it flows through the screen, thereby ensuring the purity and quality of the film. Below is a detailed explanation of the screen changer's application in the BOPP film extrusion production line:

I. Functions of the Screen Changer

Filtering Impurities: The screen changer utilizes its internal filter mesh to remove impurities, gel particles, and other foreign matter from the plasticized material, preventing them from entering the film and compromising its transparency and mechanical properties.

Protecting Equipment: The presence of impurities can also cause wear and tear or blockage in equipment such as extruders and dies. The use of a screen changer effectively mitigates these issues, prolonging the lifespan of the equipment.

Enhancing Product Quality: By filtering out impurities, the screen changer contributes to the production of purer and more uniform BOPP films, thereby enhancing the overall quality of the product.

II. Types of Screen Changers

Manual Screen Changer: This type relies on manual operation for switching the screening device, featuring a compact size and low cost. However, it is relatively slow in switching, often requiring downtime for the operation.

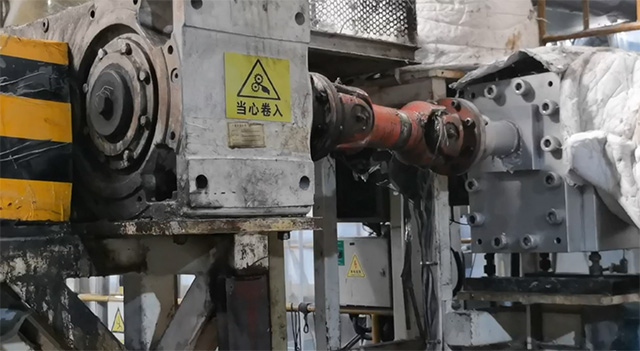

Hydraulic Automatic Screen Changer: Employing a complex hydraulic station to switch between screen plates or columns, this type offers fast screen changing and excellent back-pressure sealing. However, it comes with a higher cost and a more intricate hydraulic structure.

III. Application of Screen Changers in BOPP Film Extrusion Production Line

Installation Location: Typically installed on the extruder's melt pipe, positioned after the filter and before the die, the screen changer ensures that filtered melt can directly enter the die for extrusion.

Working Principle: As plasticized material flows through the screen changer, impurities are trapped by the filter mesh, allowing only pure melt to continue flowing forward. When the filter mesh becomes significantly clogged, it is necessary to switch to a backup filter while cleaning or replacing the clogged one.

Maintenance and Care: To maintain the screen changer's optimal performance, regular inspections, cleaning, and filter mesh replacements are essential. Additionally, keeping the area around the screen changer clean and dry prevents the ingress of impurities and moisture.

The screen changer is an indispensable component in the BOPP film extrusion production line. Through its functions of filtering impurities, protecting equipment, and enhancing product quality, it provides robust support for the production of BOPP films. When selecting and utilizing a screen changer, comprehensive consideration of the specific needs and actual conditions of the production line is crucial to ensure its optimal performance.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071