How to choose a screen changer for the installation of plastic strapping machine rope production line?

When installing a hydraulic screen changer on a plastic strapping machine production line, in order to ensure production efficiency and product quality, it is necessary to comprehensively consider multiple factors to select the appropriate screen changer. Here are some specific selection suggestions:

I. Consideration of Raw Material Characteristics

Melting Point and Melt Flow Index: Based on the melting point and melt flow index characteristics of the raw materials used in plastic strapping (such as polypropylene PP), select a screen changer that can withstand the corresponding temperature and pressure ranges.

Corrosiveness: Evaluate whether the raw materials contain corrosive substances to select the appropriate material and sealing method, ensuring the long-term stable operation of the screen changer.

Fluidity: The fluidity of the raw materials affects the screen-changing efficiency and stability of the screen changer. It is necessary to select a screen changer that can adapt to the fluidity of the raw materials.

II. Consideration of Production Requirements

Production Continuity: Plastic strapping production has high continuity requirements, so a screen changer that can quickly change screens or change screens without stopping the machine should be selected to reduce production interruptions.

Production Capacity: Based on the production capacity requirements of the production line, configure a screen changer with corresponding processing capabilities. Ensure that the screen changer can meet the production capacity requirements of the production line to avoid insufficient or excessive capacity.

III. Consideration of Extruder Type and Model

Extruder Type: Single-screw extruders and twin-screw extruders have different requirements for screen changers, so a matching screen changer should be selected.

Extruder Model: Generally, the diameter of the screen should not be less than the diameter of the screw. Select an appropriate screen changer based on the extruder model.

IV. Consideration of Screen Changer Type and Characteristics

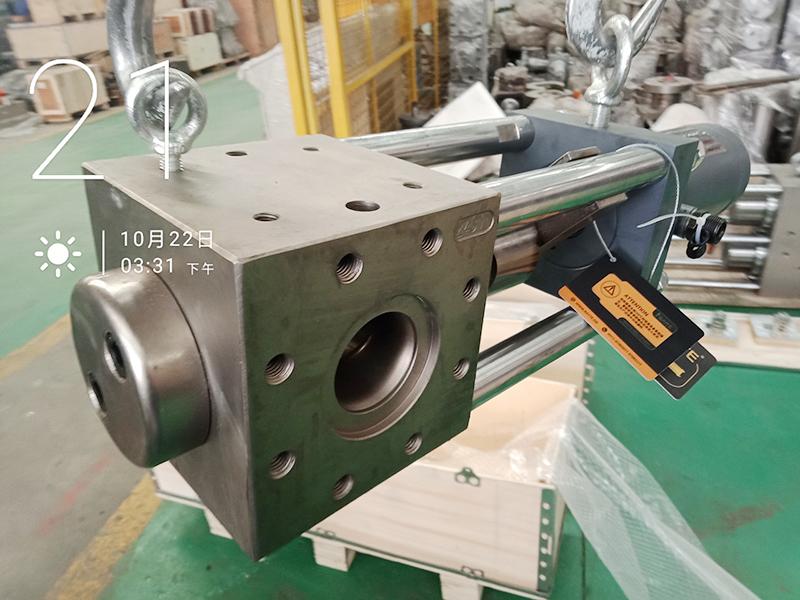

Screen Changer Types: Common types of screen changers include plate screen changers, cylindrical screen changers, four-screen circulating screen changers, and belt screen changers. Each type has its own characteristics and application scenarios, and should be selected based on the actual needs of the production line.

Plate Screen Changer: Suitable for situations requiring high screen-changing speed and accuracy.

Cylindrical Screen Changer: Suitable for processing high-viscosity, high-pressure materials.

Four-Screen Circulating Screen Changer: Performs well in specific production processes.

Belt Screen Changer: Suitable for high-precision product production with strict requirements on material pressure fluctuations.

V. Consideration of Automation Level and Operational Convenience

Automation Level: Based on the automation level of the production line, choose a manual, semi-automatic, or fully automatic screen changer. Fully automatic screen changers can significantly improve production efficiency and screen-changing accuracy.

Operational Convenience: Choose a screen changer that is easy to operate and maintain, reducing operational difficulty and labor costs.

VI. Consideration of Cost and Maintenance

Equipment Cost: Screen changers of different brands and models have significant price differences, and should be selected based on budget.

Operating Cost: Consider the energy consumption, maintenance cost, and the cost of consumables such as screen replacements for the screen changer. Choose a cost-effective screen changer to reduce long-term operating costs.

In summary, when selecting a screen changer for installation on a plastic strapping machine production line, it is necessary to comprehensively consider multiple factors such as raw material characteristics, production requirements, extruder type and model, screen changer type and characteristics, automation level and operational convenience, cost and maintenance, as well as brand and reputation. Through professional judgment and trade-offs, select the most suitable screen changer for the production line to improve production efficiency and ensure product quality.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071