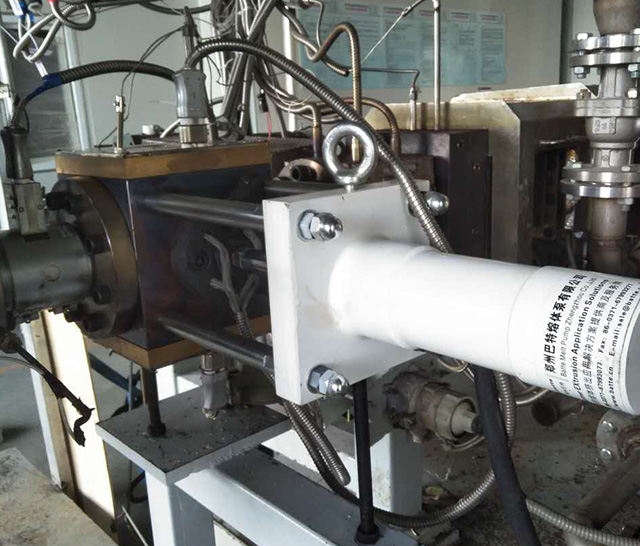

Single column hydraulic screen changer for PA granulation production line

The application of single-column hydraulic screen changers in PA (polyamide, commonly known as nylon) granulation production lines primarily demonstrates its advantages in efficient, continuous, and automated production. Below is a detailed introduction to the application of single-column hydraulic screen changers in PA granulation production lines:

I. Basic Composition and Principle of Single-Column Hydraulic Screen Changers

Single-column hydraulic screen changers consist of basic components such as the main body, column, hydraulic cylinder, screen blocks, and safety protective cover. Their working principle involves utilizing high-performance steel and special processing and heat treatment methods to ensure that two filtration channels work alternately. Two filtration channels are set on the column, containing screen blocks. These screen blocks can alternately enter the working position and the screen-changing position under the action of the hydraulic system. When it is necessary to replace the filter screen, the hydraulic device is activated to quickly switch the positions, pushing out the dirty screen position and bringing in the standby position, thereby completing the screen-changing process.

II. Advantages of Single-Column Hydraulic Screen Changers

Efficient Screen Changing: Single-column hydraulic screen changers adopt double filtration channels that work alternately, enabling rapid screen changing, significantly reducing screen-changing time, and improving production efficiency.

High Degree of Automation: Equipped with an accumulator hydraulic pump station and an electrical control cabinet (optional configuration), this screen changer can achieve automated control, reducing labor costs.

Screen Changing Without Shutdown: Single-column hydraulic screen changers are equipped with a material filling and venting structure, allowing screen changing without shutting down the machine, ensuring production continuity.

Reliable Sealing: A rigid sealing structure is adopted to ensure no leakage during the screen-changing process, guaranteeing the cleanliness of the production environment and product quality.

Wear and Pressure Resistance: The filter screen design features high wear and pressure resistance, improving the effective filtration area and filtration quality.

III. Application of Single-Column Hydraulic Screen Changers in PA Granulation Production Lines

Filtering Melt: During the PA granulation process, single-column hydraulic screen changers are used to filter impurities and particles in the melt, ensuring product quality.

Protecting Molds: By filtering the melt, single-column hydraulic screen changers can also reduce mold wear and clogging, extending mold life.

Improving Production Efficiency: The rapid screen-changing function and automated control of single-column hydraulic screen changers can significantly improve the production efficiency of PA granulation production lines.

IV. Applicability and Configuration

Single-column hydraulic screen changers are particularly suitable for melt filtration requirements in high-level automated production lines, applicable to the production of recycled granulation, cast film, blown film, sheet, plate, pipe, wire drawing, bright rod, cable, and other products. Their raw material applicability is broad, including PP, PE, ABS, PS, PET, PVB, PBT, TPE, PMMA, PC, and PA.

In terms of configuration, single-column hydraulic screen changers can be provided with standard configurations and special processing according to the actual requirements of customers. The standard configuration includes the screen changer main body, accumulator hydraulic pump station, and heating device; custom configurations add an electrical control cabinet, etc., on this basis.

In summary, single-column hydraulic screen changers have significant application advantages in PA granulation production lines, improving production efficiency, ensuring product quality, and extending mold life. When selecting single-column hydraulic screen changers, the actual needs of the production line and product characteristics should be fully considered to ensure optimal performance.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071