Will the equipment automatically switch to the backup station when the filter screen of the double column hydraulic screen changer is blocked?

When the filter mesh of a double-column hydraulic screen changer becomes clogged, it usually does not automatically switch to the standby station, but rapid screen changing can be achieved through manual operation. Below is a detailed explanation:

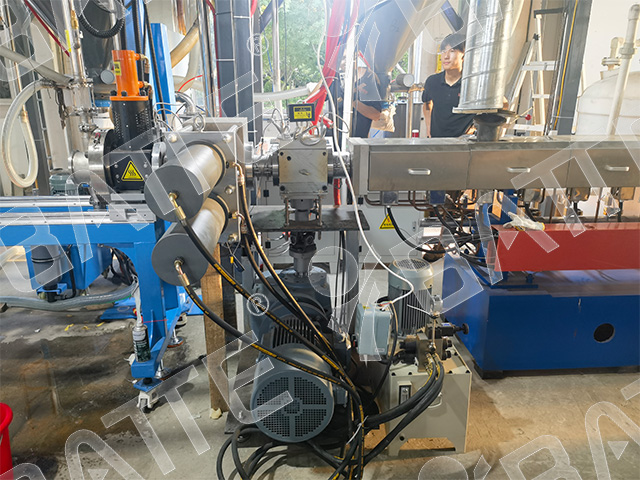

I. Working Principle of the Double-Column Hydraulic Screen Changer

The double-column hydraulic screen changer generally adopts a dual-flow channel design, featuring two filtering stations, allowing one station to operate while the other stands by. When the filter mesh on one of the stations becomes clogged, causing an increase in pressure and triggering an alarm, the operator needs to manually perform the screen changing operation.

II. Steps for Screen Changing

Alarm and Selection: After the filter mesh becomes clogged, the equipment will emit an alarm signal. At this point, the operator needs to select the station for screen changing, such as choosing Column A or Column B.

Ejecting the Old Mesh: Through the hydraulic station or other power mechanisms, the operator can start the oil pump motor and press the corresponding button to completely eject the clogged filter mesh out of the filter body.

Replacing with a New Mesh: Remove the old mesh, clear away any remaining material, and replace it with a new filter mesh. During this process, ensure that the edge wires of the new filter mesh do not protrude outside the mesh slot.

Pulling Back the New Mesh: With the motor running, press the "Pull" button to pull the cylinder back until the outer side of the mesh slot aligns flush with the side of the main body (material introduction and exhaust position). After waiting for a period of time and observing continuous and uninterrupted melt discharge, pull the cylinder to its final position, switching from the exhaust state to the working state.

III. Precautions

During the screen changing process, ensure that the oil pump motor is running and do not assemble or disassemble the filter mesh or adjust structural components of the screen changer.

If the cylinder cannot be pushed or pulled, it is usually due to clogging by hard impurities. At this point, it is strictly prohibited to increase the oil pressure and force the pushing or pulling, as this may cause greater damage.

During screen changing, due to the high temperature of the filter block, wear heat-resistant gloves to prevent it from falling or causing injury.

IV. Degree of Automation

Although the double-column hydraulic screen changer can achieve uninterrupted screen changing, ensuring the continuity and stability of production, its screen changing process still requires manual intervention. Currently, there are also more advanced automated screen changing equipment on the market that can achieve a higher degree of automation, but such equipment is usually more expensive and requires a more complex control system.

In summary, when the filter mesh of a double-column hydraulic screen changer becomes clogged, it does not automatically switch to the standby station, but rapid and continuous screen changing can be achieved through manual operation.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071