Basic structure and sealing method of automatic screen changer

The mesh belt automatic screen changer has the advantages of automation in the screen changing process, small fluctuations in material pressure and flow, and good product quality stability. It is mainly used in the production of high-quality and long process products such as chemical fiber spinning, drawing, pipe, blown film, cast film, film coating, sheet, pellet, etc., especially suitable for the production of high-precision products with strict pressure fluctuation requirements.

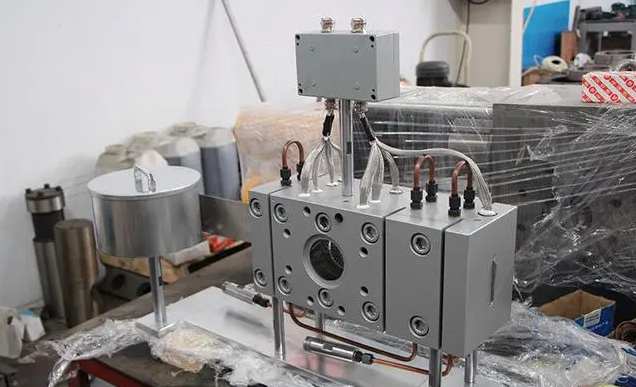

Structure composition of automatic screen changer: The mesh belt automatic screen changer is mainly composed of a seat type contrast mesh belt, a filter box, an inlet cooling section, a main flow channel connection section, an outlet cooling section, and an electronic control system.

Automatic screen changer sealing method: adopts water-cooled sealing method to ensure that the melt will not leak during operation. This sealing method can effectively prevent high-temperature melt leakage, ensuring production safety and stability, while also reducing raw material waste and environmental pollution.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071