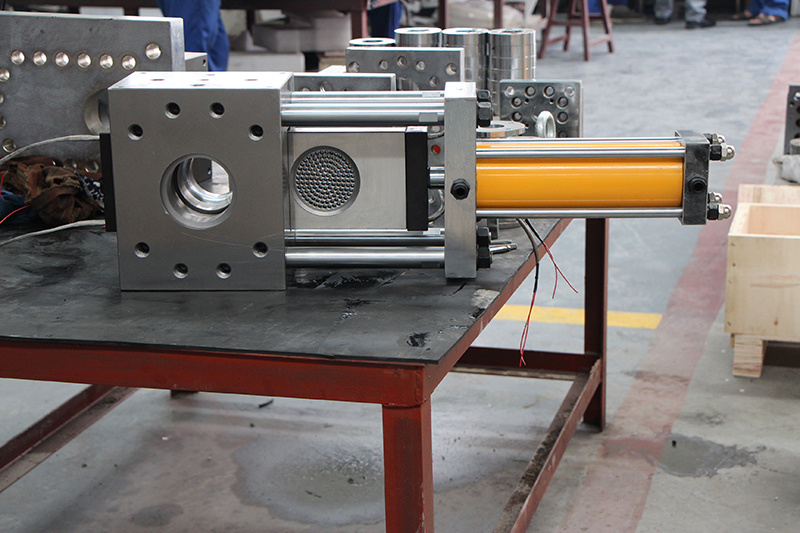

Four major advantages of single plate screen changer

Single plate screen changer has the following advantages:

1、 Has minimal impact on production. The flow channel is short, and the path for materials to pass through the screen changer is short, resulting in minimal temperature and pressure changes in the material flow after passing through the screen changer. This can minimize the impact on the production process, ensure the stability and consistency of product production, and is particularly important for materials that are sensitive to temperature and pressure changes.

Fast network replacement, capable of completing the replacement operation in a short period of time. Generally, the fast network replacement time can be less than 2 seconds, which can achieve non-stop and fast network replacement, greatly improving production efficiency.

2、 In terms of structure and performance. The single plate screen changer has a high load-bearing capacity and can withstand significant material flow pressure structurally. It has good adaptability to some high-pressure extrusion production processes and can meet the needs of different production scenarios. Large filtering area, with a large filtering area, can effectively filter out impurities and foreign objects in materials, improving product quality. The filter design with high anti-wear, high pressure resistance, and high precision can further improve the filtration effect and quality.

Good sealing performance, through reasonable sealing structure design, such as using wide sealing surfaces, thick seals, etc., it has good sealing performance, can prevent material leakage, and ensure the safety and stability of the production process. Easy to operate, relatively simple in structure, convenient to operate, and easy to maintain and upkeep. Operators only need to undergo simple training to master the operation method of the screen changer.

3、 In terms of cost, the price is relatively low. Compared with some complex screen changers, the manufacturing cost of single plate screen changers is relatively low, and the price has certain advantages, which can reduce equipment procurement costs for enterprises. Low energy consumption, low energy consumption during operation, can save energy consumption for enterprises and reduce production costs.

4、 Good installation adaptability. Easy to install, can be directly installed on the heads of various models of plastic extruders, without the need for excessive modifications to the original extrusion equipment, has strong adaptability, and is convenient for enterprises to upgrade and transform their equipment. Modular combination, usually using modular design, can be combined and adjusted according to different production needs to meet the requirements of different production lines.

In summary, single plate screen changers have advantages such as minimal impact on production, excellent structural performance, low cost, and good installation adaptability. They have been widely used in extrusion production in industries such as plastics, rubber, and chemical fibers.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071