What are the advantages of the dual-column hydraulic continuous screen changer?

The advantages of the dual-column hydraulic continuous screen changer can be detailed as follows:

Continuous Production Capability:

Adopting a dual-column dual-flow channel design, it allows two screens to work simultaneously. When one screen needs to be replaced, the other can continue working, realizing the function of screen changing without stopping the machine. This design ensures the continuity and stability of the production process, avoiding production interruptions caused by screen changing.

High Filtration Efficiency:

The large surface area of the screen provides higher filtration efficiency. It can effectively filter out impurities and particles in melts such as plastics and rubbers, thereby ensuring product quality and purity.

Pressure Stability:

During the screen changing process, due to the presence of a standby screen, the material flow pressure fluctuation is small. This helps maintain the stability of the extrusion process and reduces production problems that may be caused by pressure fluctuations.

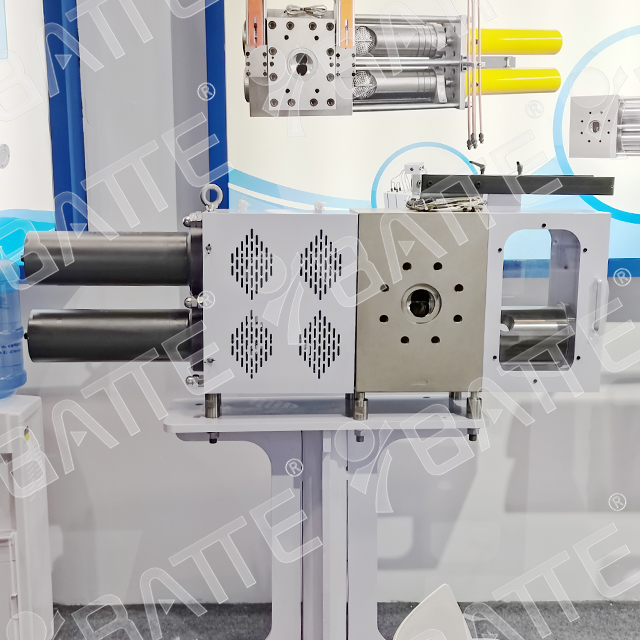

Sturdy and Durable Structure:

The main body is usually made of high-quality alloy steel and undergoes nitriding treatment, enhancing its hardness and wear resistance. This structure enables the dual-column hydraulic continuous screen changer to have strong carrying capacity, enabling stable operation for a long time and extending its service life.

Ease of Operation:

The screen changing process is highly automated, reducing the labor intensity of workers. An optional mobile installation cart integrates the hydraulic station and electrical control system, making on-site maintenance and repairs more convenient.

Safety Design:

Equipped with a safety shield, it effectively prevents accidental injuries during operation. This design ensures the personal safety of operators and reduces potential safety risks.

Wide Range of Applications:

It is suitable for various production requirements, such as granulation, pipe, sheet, chemical fiber, cast film, and various chemical solvents. It is particularly suitable for production scenarios requiring uninterrupted material flow and high continuity during screen changing, meeting the diverse needs of different industries.

In summary, the dual-column hydraulic continuous screen changer, with its advantages of continuous production, high filtration efficiency, stable pressure, sturdy structure, ease of operation, safety design, and wide range of applications, has significant advantages and broad application prospects in the field of melt filtration for plastics, rubbers, and other materials.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071