Plastic Bottle Extrusion Screen Changer

The Plastic Bottle Extrusion Screen Changer is a critical piece of equipment used in the extrusion production process of plastic bottles. Its main function is to filter out foreign particles and impurities in the plasticized material flow, ensuring product quality and production efficiency. Below is a detailed introduction to the Plastic Bottle Extrusion Screen Changer:

I. Definition and Purpose

The Plastic Bottle Extrusion Screen Changer is a manual or automatic switching device that includes one or more screens. It can effectively remove foreign particles, aged or deteriorated particulate matter, low-precision particulate matter in recycled materials, various non-plastic substances in recycled materials, and plastics with incompatible characteristics from the plasticized material flow as it passes through the screen. This device has a wide range of applications in plastic bottle extrusion lines and is of great significance for improving product quality and ensuring the continuity and stability of production.

II. Structure and Working Principle

Structure:

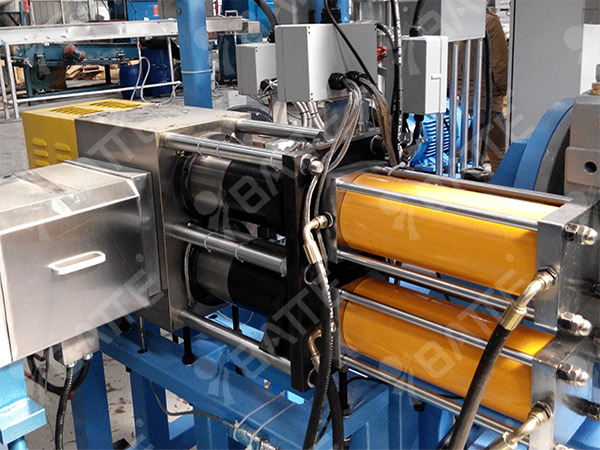

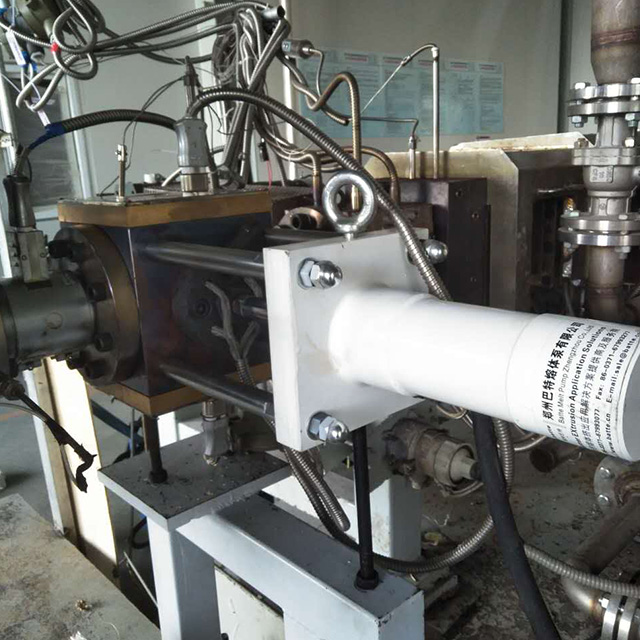

The Plastic Bottle Extrusion Screen Changer typically consists of screens, alloy porous plate supports, carriers, switching mechanisms, and other components. The screens are installed on an alloy porous plate, which is then mounted on a plate-type or column-type carrier. The carrier can be moved to switch between the working position and the offline non-working position within the system.

Working Principle:

During the plastic bottle extrusion process, the plasticized material flows through the screen changer, and impurities are retained by the screens. When the screens become clogged to a certain extent, the switching mechanism will switch the screens and their supporting carriers from the working position to the offline non-working position, while another carrier with new screens is switched to the working position to achieve continuous production.

III. Types and Characteristics

Types:

Based on the switching method, Plastic Bottle Extrusion Screen Changers can be divided into manual screen changers and automatic screen changers. Manual screen changers require manual operation to switch screens, while automatic screen changers achieve automatic switching through electrical or hydraulic control systems. Based on the number of screens, they can also be classified as single-screen changers, double-screen changers, and multi-screen circulating changers.

Characteristics:

Excellent filtration effect: It can efficiently remove impurities from plasticized materials, improving product quality.

Strong production continuity: Automatic screen changers can achieve screen changing without stopping the machine, ensuring the continuity and stability of production.

Strong adaptability: Screens of different precision levels can be selected according to different production needs and process requirements.

IV. Application and Maintenance

Application:

Plastic Bottle Extrusion Screen Changers are widely used in various plastic bottle extrusion lines, such as PET bottles, PP bottles, PE bottles, etc. They are also applicable to other extrusion lines, such as polymer (plastic and rubber) molding lines and ceramic extrusion lines.

Maintenance:

Regularly check the clogging of screens and clean or replace them in a timely manner.

Keep the screen changer and its surrounding environment clean to prevent impurities from entering the interior of the screen changer.

Regularly check the flexibility and reliability of the switching mechanism to ensure smooth screen changing.

V. Precautions

When selecting a Plastic Bottle Extrusion Screen Changer, choose the appropriate type and specification based on production needs and process requirements.

During installation and use, strictly follow the operating manual to avoid equipment damage or production accidents due to misoperation.

Regularly maintain and service the screen changer to extend its service life and improve production efficiency. In summary, the Plastic Bottle Extrusion Screen Changer plays an irreplaceable role in the extrusion production process of plastic bottles. By selecting the appropriate type, using it correctly, and maintaining it scientifically, the smooth progress of the production process and the improvement of product quality can be ensured.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071