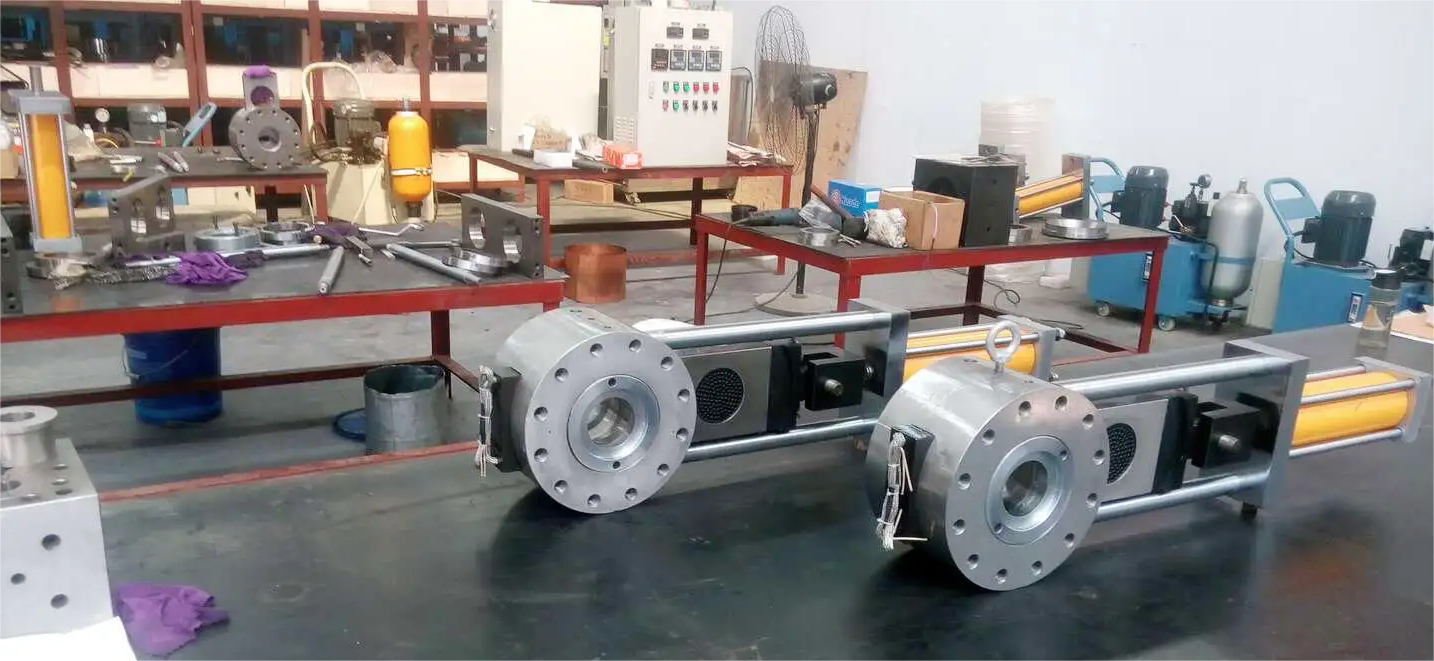

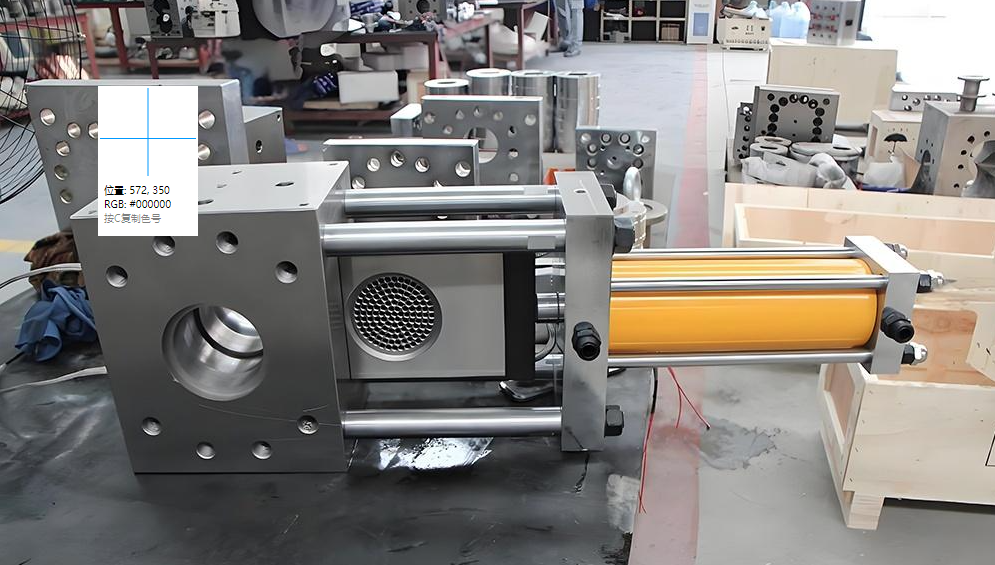

Pearl cotton single plate hydraulic screen changer

The pearl cotton veneer hydraulic screen changer plays a crucial role in the production process of pearl cotton. The following are its main functions and characteristics:

The function of pearl cotton veneer hydraulic screen changer

The main function of the pearl cotton veneer hydraulic screen changer is to filter the plastic melt before it enters the mold head, ensuring the purity of the melt entering the mold head, thereby improving the quality of pearl cotton products. By filtering out foreign particles and impurities, the screen changer can prevent these impurities from blocking the spray holes of the mold head, thereby avoiding problems such as uneven foaming of pearl cotton, excessive or insufficient local density, and ensuring its buffering performance and appearance quality.

Characteristics of pearl cotton veneer hydraulic screen changer

Structural features: Overall design: Pearl cotton veneer hydraulic screen changers usually adopt an overall structural design to ensure the stability and durability of the structure. High strength materials: The main body is usually made of high-strength tool steel, which has sufficient rigidity and corrosion resistance to withstand high temperature and high pressure plastic melts. Skateboard structure: There are two or more filtering stations on the skateboard for installing filter screens. Skateboards are typically made of alloy steel or other wear-resistant materials to ensure their stability and wear resistance under high temperatures and pressures.

Functional features: Quick switching: The pearl cotton veneer hydraulic screen changer can achieve quick switching of filtering stations, with rapid screen changing action and minimal changes in material flow, thereby reducing interference with the production process. High voltage resistance: The network converter has high voltage resistance performance and can meet the needs of high-voltage production environments. Large filtration area: The filter area of the screen changer is large, the flow channel is short and straight, and there are no dead corners, which can ensure the smooth passage of materials and improve production efficiency. Fast heating speed: Using internal heating method, the heating speed is fast, the temperature is uniform, the energy consumption is low, which helps to maintain the stability and efficiency of the production process.

Operation characteristics: Simple screen replacement: The operation of the pearl cotton veneer hydraulic screen changer is relatively simple and fast, generating less waste during screen replacement and reducing production costs. Non-stop replacement: The screen changer supports non-stop replacement of filter screens, reducing production interruption time and improving equipment utilization and production efficiency.

Application features: Wide applicability: Pearl cotton veneer hydraulic screen changer is suitable for production needs of different yields, with filter screen diameters ranging from 70mm to 400mm, and can meet production lines of various scales. Flexibility: It can be equipped with a fast hydraulic replacement system, quick screen replacement, and a wide range of filter diameters to meet the high extrusion production of any polymer.

In summary, the pearl cotton veneer hydraulic screen changer plays an important role in the production process of pearl cotton due to its unique function and significant characteristics, providing strong guarantees for improving product quality and production efficiency.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071