Innovative Screen Changer Technology Enhances Plastic Film Extrusion Efficiency

In the ever-evolving world of plastic film manufacturing, staying ahead of technological advancements is crucial for maintaining competitive edge and production efficiency. One such innovation making waves in the industry is the advanced screen changer for plastic film extruders. This technology is revolutionizing the extrusion process by ensuring consistent quality and reducing downtime.

The Role of Screen Changers in Plastic Film Extrusion

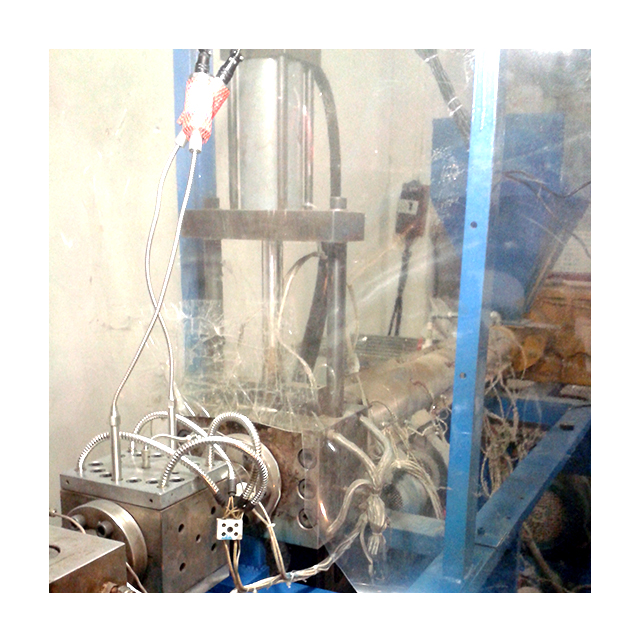

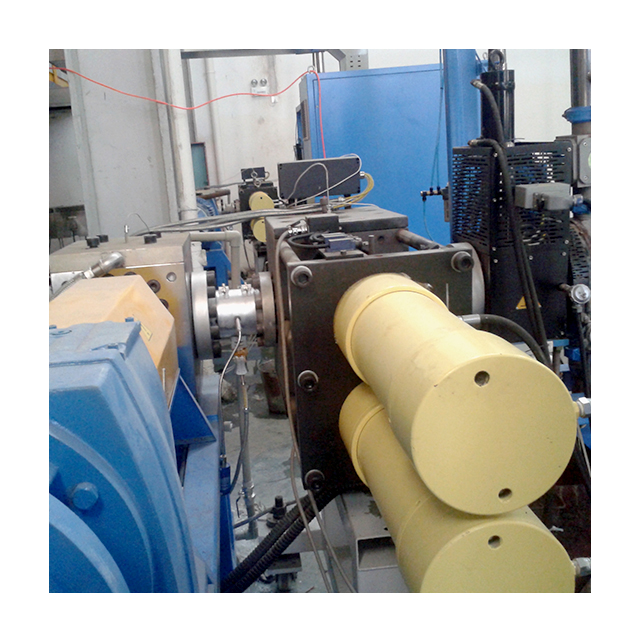

Screen changers are critical components in the plastic extrusion process. They are designed to filter out contaminants from the molten plastic, ensuring a clean and consistent flow of material through the extruder. This filtration is essential for producing high-quality plastic films with minimal defects.

Key Benefits of Using Screen Changers:

Contaminant Removal: Screen changers effectively filter out impurities, leading to cleaner and higher-quality extruded films.

Continuous Production: Automatic screen changers allow for continuous operation without the need to stop the extruder for screen replacement, significantly reducing downtime.

Improved Product Consistency: By maintaining a consistent flow of clean molten plastic, screen changers help produce films with uniform thickness and quality.

Extended Equipment Life: Reducing contaminants in the extrusion process can also extend the lifespan of downstream equipment, such as dies and rollers.

Latest Advancements in Screen Changer Technology

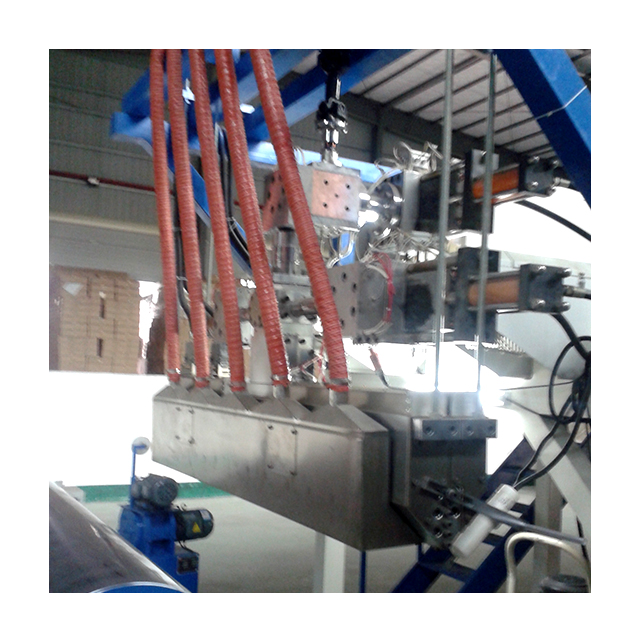

Recent advancements in screen changer technology have focused on enhancing automation, precision, and ease of use. Modern screen changers are equipped with advanced control systems that allow for seamless operation and real-time monitoring. These systems can automatically detect when screens need to be changed and can do so without interrupting the production process.

Features of Advanced Screen Changers:

Automated Operation: Reduces the need for manual intervention, minimizing human error and increasing efficiency.

Real-Time Monitoring: Provides operators with real-time data on screen condition and contamination levels, enabling proactive maintenance.

Enhanced Durability: Made from high-quality materials that withstand the harsh conditions of the extrusion process, ensuring long-lasting performance.

User-Friendly Design: Easy to install and operate, with intuitive controls that simplify the screen changing process.

Industry Impact and Future Outlook

The adoption of advanced screen changer technology is transforming the plastic film extrusion industry. Manufacturers are experiencing significant improvements in production efficiency, product quality, and overall operational costs. As the demand for high-quality plastic films continues to grow, the importance of reliable and efficient screen changers cannot be overstated.

Looking ahead, the industry can expect further innovations in screen changer technology, including enhanced filtration capabilities, greater integration with Industry 4.0 systems, and more sustainable materials. These advancements will continue to drive the evolution of plastic film extrusion, helping manufacturers meet the ever-increasing demands of the market.

The integration of advanced screen changer technology in plastic film extruders is a game-changer for the industry. By ensuring a clean and consistent flow of molten plastic, these devices play a crucial role in enhancing product quality and production efficiency. As technology continues to advance, manufacturers who invest in cutting-edge screen changers will be well-positioned to lead the market and meet the future demands of the plastic film industry.

Stay updated with the latest innovations in screen changer technology and explore how these advancements can benefit your production process. Embrace the future of plastic film extrusion with state-of-the-art screen changers and experience the difference in quality and efficiency.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071