Plastic Continuous Extrusion Screen Changer: A Revolutionary Technology for Boosting Production Efficiency

In the plastic processing industry, continuous extrusion technology has always been crucial for enhancing production efficiency and product quality. Recently, an innovative device known as the plastic continuous extrusion screen changer has garnered significant attention in the market. This equipment brings revolutionary changes to the plastic extrusion molding process with its unique continuous screen-changing function.

The plastic continuous extrusion screen changer is an auxiliary device specifically designed for use in the plastic extrusion molding process. Its primary function is to achieve continuous screen replacement without interrupting production, thereby effectively avoiding production disruptions and waste generation due to screen clogging. This feature renders the plastic continuous extrusion screen changer extremely valuable in the plastic processing industry.

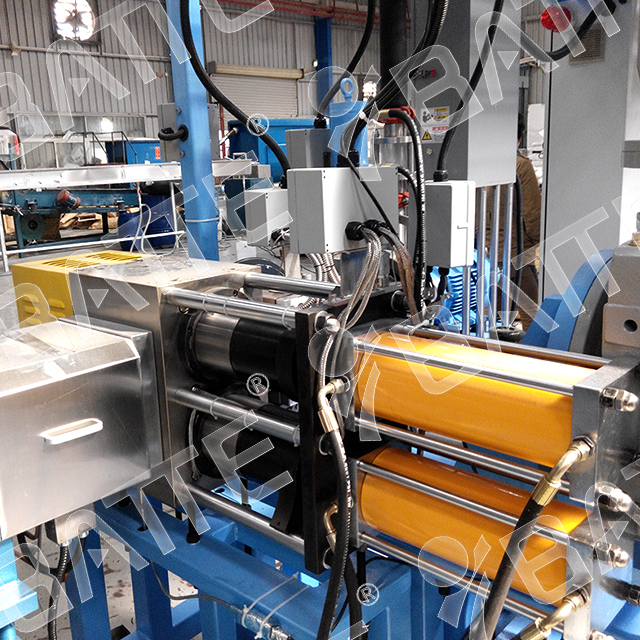

It is reported that this plastic continuous extrusion screen changer adopts an advanced dual-piston design, with each piston housing a filtering chamber. When a screen replacement is needed, one piston is removed from the housing, while the other remains in the working position. At this point, operators can easily take out the dirty screen pack and replace it with a new one. Subsequently, the removed piston is repositioned in the housing and resumes operation after a venting phase. During this process, the other piston undergoes the same screen replacement operation. This design ensures the continuity and efficiency of screen replacements, significantly enhancing production efficiency.

In addition to its continuous screen-changing function, this plastic continuous extrusion screen changer boasts several other advantages. For instance, its main body is constructed from alloy steel and undergoes nitriding treatment, imparting extreme hardness and wear resistance to the equipment. Meanwhile, the flow channel of the device has undergone chromium plating, further enhancing the surface hardness and corrosion resistance. These features enable the plastic continuous extrusion screen changer to maintain stable performance over extended use, reducing maintenance and replacement costs.

In terms of applications, the plastic continuous extrusion screen changer is widely used in various plastic extrusion molding processes, such as nonwoven fabrics, pelletizing, pipe, plate, sheet, and cast film production. It is particularly indispensable in equipment like nonwoven fabric extruders, plastic pelletizing machines, PP/PE pipe extrusion lines, and PP/PE plate extruders.

With the continuous development of the plastic processing industry, market demands for plastic extrusion molding equipment are becoming increasingly stringent. Traditional screen replacement methods are not only inefficient but also prone to production disruptions and waste generation. The emergence of the plastic continuous extrusion screen changer addresses this issue. With its unique continuous screen-changing function and exceptional performance, it has garnered widespread market recognition and praise.

Looking ahead, with ongoing technological advancements and market development, the plastic continuous extrusion screen changer is poised to play an even more significant role in the plastic processing industry. It will provide more efficient, stable, and reliable solutions for the plastic extrusion molding process, driving the sustained development and progress of the entire industry.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071