Revolutionizing Extrusion with the New Manual Screen Changer for Extruder

Industry-Leading Innovation Simplifies Maintenance and Boosts Efficiency

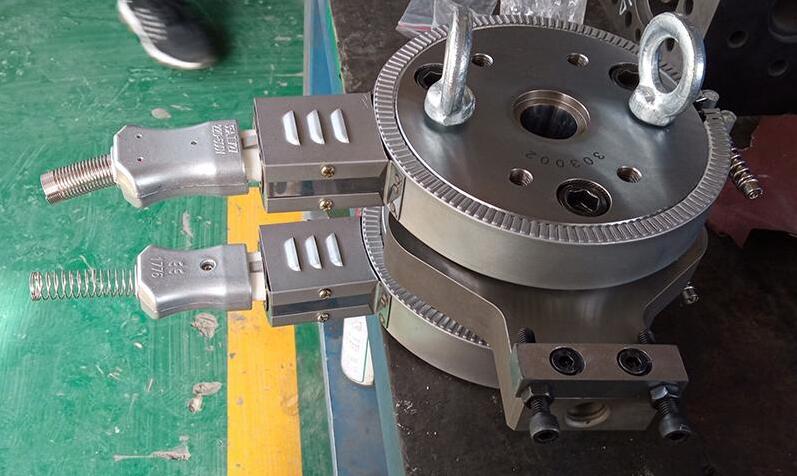

In a groundbreaking move that promises to redefine the extrusion process, Batte melt pump is thrilled to announce the launch of its new Manual Screen Changer for Extruder. Designed with cutting-edge technology and user-friendly features, this state-of-the-art equipment is set to transform the way manufacturers approach screen maintenance and operational efficiency.

The Need for Innovation

Extrusion processes are vital in various industries, from plastics and rubber to food and pharmaceuticals. However, one persistent challenge has been the time-consuming and labor-intensive task of changing screens, which can lead to downtime and increased production costs. Recognizing this issue, Batte melt pump developed a manual screen changer that not only addresses these concerns but also enhances overall productivity.

Key Features and Benefits

User-Friendly Design

The Manual Screen Changer for Extruder boasts an intuitive design that makes screen changes quick and effortless. Operators can easily access and replace screens without the need for complex tools or extensive training, significantly reducing downtime.

Enhanced Efficiency

With this manual screen changer, manufacturers can expect a significant boost in operational efficiency. The quick and seamless screen change process minimizes production interruptions, ensuring a smoother and more consistent extrusion flow. This, in turn, leads to higher output and improved product quality.

Durability and Reliability

Built with robust materials, the Manual Screen Changer for Extruder is designed to withstand the rigorous demands of industrial use. Its sturdy construction ensures long-term durability and reliability, minimizing the need for frequent repairs or replacements.

Cost-Effective Solution

By streamlining the screen change process and reducing downtime, the manual screen changer offers a highly cost-effective solution. It eliminates the need for additional labor and minimizes waste, contributing to overall cost savings and a better bottom line.

Early adopters of the Manual Screen Changer for Extruder have reported impressive results. Manufacturers across different industries have praised its ease of use, efficiency, and durability. With its ability to minimize downtime and maximize output, this innovative product is poised to make a significant impact on the market.

The launch of the Manual Screen Changer for Extruder marks a significant milestone in Batte melt pump's journey to revolutionize extrusion processes. This groundbreaking product offers manufacturers a robust, user-friendly, and cost-effective solution that promises to enhance efficiency, improve product quality, and drive overall business growth.

Join the ranks of forward-thinking manufacturers and experience the benefits of the Manual Screen Changer for Extruder today.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071