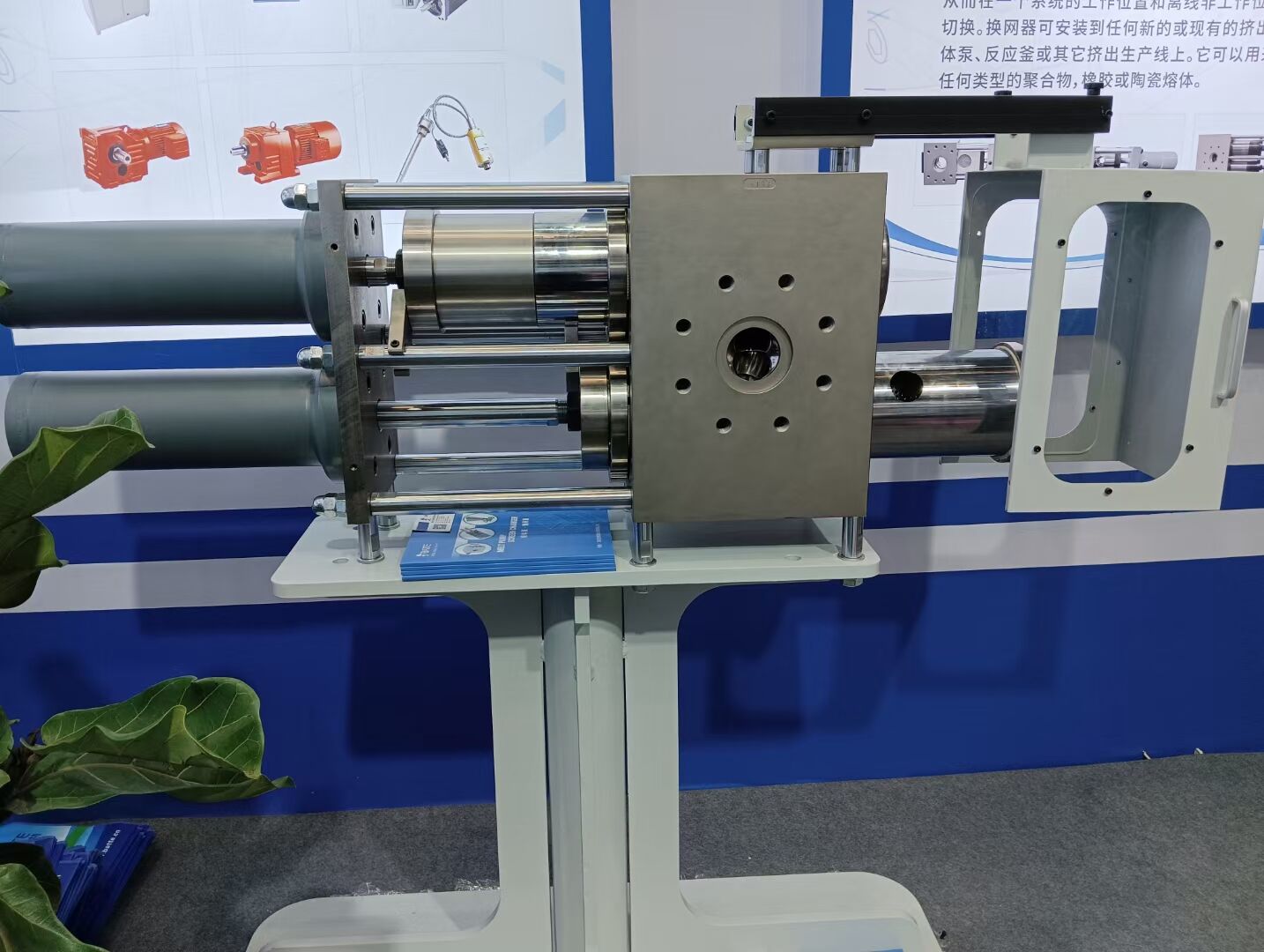

Double-column large-area screen changer

Double-column large-area filter screen changer realizes continuous production and high-precision filtration, which is suitable for high-end films, medical packaging, engineering plastics granulation and other scenarios, and effectively intercepts impurities, improves quality, and meets the needs of 24-hour uninterrupted production. With its continuous production and high filtration accuracy, the double-column large-area filter screen changer is mainly used in the following scenarios:

1、Plastic extrusion processing

High-end film/sheet production (e.g. BOPP, CPP, PET sheet):

Large-area filter effectively intercepts tiny impurities, reduces crystal spots and black spots, and improves optical performance and surface quality.

Pipe/profile extrusion (e.g. PVC pipe, PE gas pipe):

Double-column alternating screen change avoids downtime and guarantees pressure stability when extruding thick-walled products.

Medical/food grade packaging materials:

High-precision filtration (up to 20μm or less) meets hygiene standards and avoids the risk of contamination.

2、Plastic pelletizing (new and recycled materials)

Engineering plastics pelletizing (such as PA, PC, ABS):

High temperature and high pressure resistant design to adapt to high viscosity melt filtration and prevent degradation.

Recycling line for recycled plastics:

Strongly intercept the carbonized particles, metal shavings and other impurities in the recycled material to improve the purity of the recycled material.

3、Rubber and elastomer processing

Tire seal/rubber tube extrusion:

Cope with the vulcanized rubber particles, fibers and other impurities in the rubber to extend the die life.

TPE/TPU thermoplastic elastomer:

Reduce gel and unmelted matter, safeguard product elasticity and surface finish.

4、Specialty materials with high requirements

Biodegradable plastics (PLA/PBAT):

Prevent the degradation of hydrolysis-sensitive materials due to downtime and screen change.

High viscosity materials (such as hot melt adhesives, cable materials):

Optimize runner design to reduce melt retention and avoid thermal oxidation.

5、Large continuous production line

24 hours non-stop production:

Double-column alternating screen change to realize “zero downtime”, suitable for auto parts, building materials and other high-volume orders.

High extrusion volume scenario (e.g. above 300kg/h):

Large screen area reduces pressure fluctuation and matches high power extruder.

Core advantages and scenario matching

Continuous production: key for medical materials, multi-layer co-extrusion and other scenarios that cannot be stopped.

High-precision filtration: suitable for products sensitive to impurities such as optical film and lithium battery diaphragm.

High-pressure tolerance: for high-pressure extrusion conditions such as engineering plastics and high-temperature rubber.

Email: sale@meltpump.com

WhatsApp: +86 158 38331071