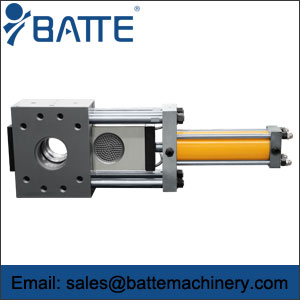

extrusion melt filter for plastic

We are specialized in the research and manufacturing of extrusion melt filter for plastic for more than 20 years. With strong scientific research team and mature technology; hold many and national invention patents.

Our items can not only filter impurities, but also can greatly improve the plasticizing and homogenization effect of the raw material, make the product structure more homogeneous and product surface smoothness and quality much better, energy-saving and consumption-reducing, output- increasing and labor-saving.

Plastic melt through the extruder filter plate go into the crosshead, then turn 90 degree, flow along the wire guide rod, converging into a closed ring, through the mouth mould coating on the metal conductor. Because the core through the conductor guide bar continuous movement, make wire coating can produce continuous, get the continuous wire products.

Single-plate hydraulic screen changer with double working positions specifications:

|

Type

|

Output

Kg/h

|

Size (mm)

|

Screen size

|

Heating tube

|

|

L1

|

L2

|

L3

|

L4

|

Ф(mm)

|

cm2

|

V

|

KW

|

|

ZB-SSP-A-70

|

75~200

|

100

|

715

|

170

|

240

|

Ф70

|

38

|

230/400

|

3.5/5.8

|

|

ZB-SSP-A-100

|

130~350

|

110

|

815

|

185

|

280

|

Ф100

|

78

|

230/400

|

4.5/6.8

|

|

ZB-SSP-A-120

|

200~550

|

130

|

880

|

205

|

320

|

Ф120

|

113

|

230/400

|

5.2/7.2

|

|

ZB-SSP-A-150

|

350~800

|

150

|

990

|

235

|

360

|

Ф150

|

176

|

230/400

|

6.5/8.5

|

|

ZB-SSP-A-180

|

450~1250

|

160

|

1035

|

245

|

360

|

Ф180

|

254

|

230/400

|

7.6/9.5

|

|

ZB-SSP-A-200

|

550~1500

|

180

|

1155

|

280

|

420

|

Ф200

|

314

|

230/400

|

8.5/11

|

|

ZB-SSP-A-250

|

800~2500

|

225

|

1260

|

300

|

430

|

Ф250

|

490

|

230/400

|

9.5/12

|

|

ZB-SSP-A-300

|

1200~3500

|

260

|

1440

|

380

|

500

|

Ф300

|

706

|

230/400

|

11.5/15.5

|

|

ZB-SSP-A-320

|

1500~4000

|

300

|

1660

|

400

|

560

|

Ф320

|

803

|

230/400

|

13/17.5

|

|

Type

|

Output

Kg/h

|

Size (mm)

|

Screen size

|

Heating tube

|

|

L1

|

L2

|

L3

|

Ф(mm)

|

cm2

|

V

|

KW

|

|

ZB-SSP-B-70

|

75~200

|

115

|

715

|

170

|

Ф70

|

38

|

230/400

|

3.5/5.8

|

|

ZB-SSP-B-100

|

130~350

|

135

|

815

|

185

|

Ф100

|

78

|

230/400

|

4.5/6.8

|

|

ZB-SSP-B-120

|

200~550

|

150

|

880

|

205

|

Ф120

|

113

|

230/400

|

5.2/7.2

|

|

ZB-SSP-B-150

|

350~800

|

170

|

995

|

235

|

Ф150

|

176

|

230/400

|

6.5/8.5

|

|

ZB-SSP-B-180

|

450~1250

|

185

|

1120

|

245

|

Ф180

|

254

|

230/400

|

7.6/9.5

|

|

ZB-SSP-B-200

|

550~1500

|

225

|

1255

|

280

|

Ф200

|

314

|

230/400

|

8.5/11

|

|

ZB-SSP-B-250

|

800~2500

|

260

|

1325

|

300

|

Ф250

|

490

|

230/400

|

9.5/12

|

|

ZB-SSP-B-300

|

1200~3500

|

285

|

1470

|

380

|

Ф300

|

706

|

230/400

|

11.5/15.5

|

|

ZB-SSP-B-320

|

1500~4000

|

300

|

1660

|

400

|

Ф320

|

803

|

230/400

|

13/17.5

|