Structure and working principle of plate type screen exchanger

It is one of the most widely used and most widely used equipment for plastic extrusion in plastic extrusion system. It is suitable for all thermoplastic plastics such as sheet, sheet, pipe and blow film. Among them, the single plate mesh changer has advantages such as short flow path and small volume.

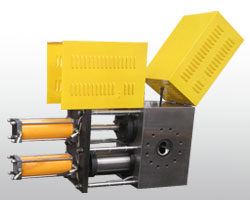

The plate type screen changer is composed of two main parts. That is, the exchanger itself and the hydraulic system that controls it. The mesh screen changer includes a slide plate (it has two filter plates and nets), seals, shell or body and control cylinder. The hydraulic part is a large system with a pressure of up to 3000PSi. The purpose of using the screen changer is to ensure that one of the two sets of filtration devices is in the flow path of the extruded material at any time during operation. The replacement is to move the new network group into the production line by moving the skateboard of the flow of molten material swiftly to enter the production line and remove the used mesh groups for cleaning or replacement. One end of the skateboard is attached to a hydraulic piston. When changing the network, the skateboard hydraulic drive and cross cutting flow, so that the new network group into operation. All these are completed in one second or even shorter time, while maintaining regular sealing to prevent leakage when the material flows through. In view of the different quality requirements of the products, the network changer manufacturers have introduced the column changer and the four network circulation changer, which can satisfy the users' high demand for the products.